When the concept of the 3D printer was first introduced to the general public, it captured people’s imaginations like few things ever had before. Some could just call it a high-tech manufacturing technique and not be wrong, but the idea of creating a physical object from nothing more than a computer file is definitely an exciting one. It also has almost limitless potential for a number of industries. Crucial medical devices can be made to fit a patient’s specific needs, and manufacturers wouldn’t need to worry about a machine not having exactly the right part to function.

What is 3D Printing?

According to 3dprinting.com, 3D printing is the process of additive manufacturing whereby an individual takes a computer file of an object that is to be constructed and converts it into a three dimensional physical object.

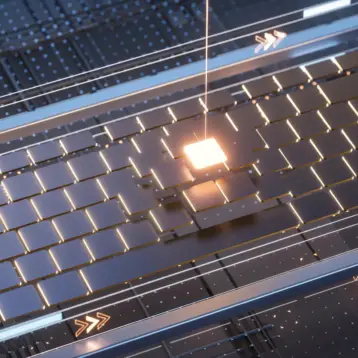

How 3D Printing Works

In the most simplistic sense, the computer works from an image file and constructs the actual physical object layer by layer from a special filament. This filament can be made from small particles of plastic, metal, ceramic or glass powder fused together into a mass that has the desired shape. The interesting thing is that although the process of creating a physical object is done through layering, there are no visible signs of the layering once an object has been completed. This enables 3D printing to be used in unlimited applications that could apply to various industries. Two such industries are the medical field and space.

3D Printing, PVA Filament, and Medical Applications

Different types of filaments are used in 3D printing, but one that has proven to be very useful in a number of applications is polyvinyl alcohol, or PVA. PVA has a white translucent appearance, and it is highly resistant to oil and grease. According to Gizmo Dorks, a supplier of PVA filament, it also has excellent adhesive properties and a high threshold for maximum stress before it breaks (tensile strength). Its low melting point of 190 degrees Celsius means that it is easy to use with a 3D printer, and the fact that it is water soluble means that it is an excellent option for support material for intricate printing projects.

One of the most exciting possibilities of 3D printing is how it can be applied to the medical industry, and part of that is due to PVA filament. PVA is commonly used for cartilage replacement and in orthopedic implants thanks to its high water content, flexibility and tensile strength. Thanks to 3D printing technology, medical implants made from PVA can be more intricate than ever before. They can be made to the very specific needs of a patient using a safe and bio-compatible material.

3D Printing and Space

Another possible application of 3D printing that has experts very excited has to do with the space shuttle. The space shuttle and space stations require very precise parts and tools in order to function properly. Informationweek.com reported that the failure of a shuttle’s equipment or tools could prove disastrous, so the idea that these elements can be made to order even in zero gravity using 3D printing technology could change space travel forever. A 3D printer could reduce the cargo weight and volume on a space shuttle, making launches and other missions safer than ever, while the shuttle crew could simply have whatever tools or parts they need in minutes.

3D printing is still a relatively new technology, but so far it has proven to be precise and useful enough to be very useful in a number of applications. It is seen as the wave of the future, and it could change the medical, space exploration and manufacturing industries forever.