Supercritical fluid chromatography (SFC) is an important analytical tool used in many laboratories. It effectively separates and purifies material. An appropriate choice of a preparative SFC system significantly increases productivity and reliability of results. This guide will, they hope, eliminate some unnecessary steps.

Understanding Preparative SFC Systems

Supercritical fluids are mobile phases used in prep SFC. This approach can achieve faster separations with less solvent waste than standard techniques.

Preparative SFC is a larger-scale application. It is important for labs that purify and isolate substances. It impacts system efficiency, throughput, and cost.

Key Considerations

1. Requirements of the Lab

Determine the lab’s requirements. Consider the scale, types of compounds, and purity needed. Some laboratories require high-throughput systems, and others seek trace solutions.

2. Performance and Efficiency

Evaluate the system’s performance. Consider variables such as flow rate, pressure capacity, and separation efficiency. A high-throughput system can considerably reduce processing time.

3. Flexibility and Versatility

And to turn it into the ability to do all the different tasks as they come. Modular designs stand for simple upgrades or changes in some systems. This opens the possibility of a longer life and more usefulness of the system.

Technical Specifications

1. Detection Options

Different detectors suit different applications. Mass spectrometry can give you more detailed information, but it isn’t an off-the-shelf UV detector. Select according to the compounds and sensitivity required.

2. Column Compatibility

Make sure it works on multiple columns. This enables task-specific optimization for separation. We can have different effects on resolution and selectivity with different columns.

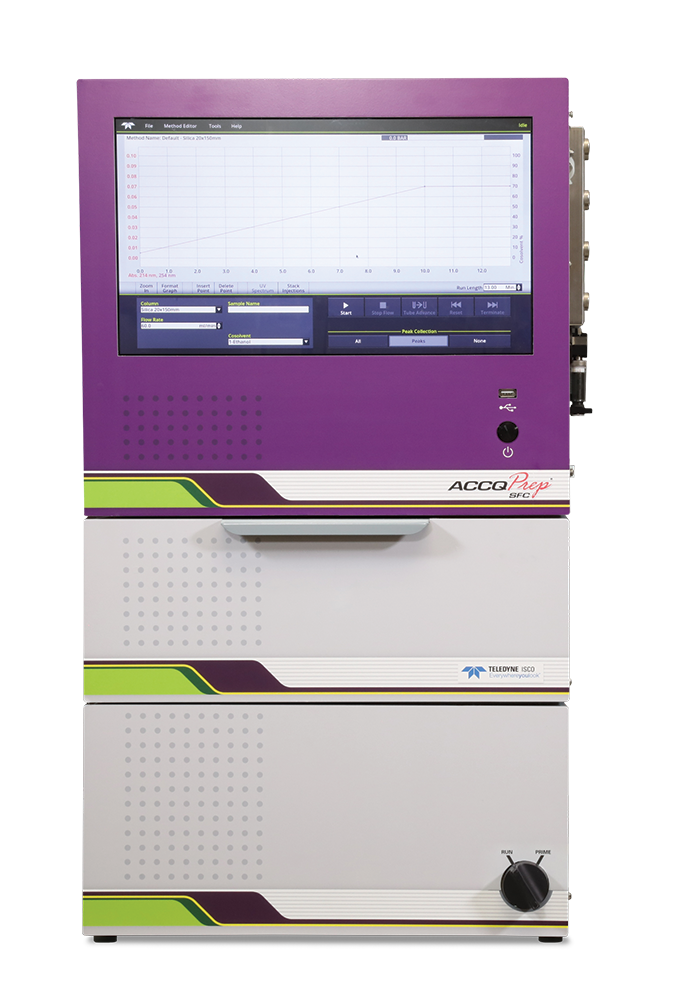

3. Software and Control

Most modern systems are supplied with advanced software. This will make it much easier to operate and manage data. Efficient and errorless automation of processes can be achieved through user-friendly interfaces.

Cost Considerations

1. Initial Investment

One downside is the high upfront cost associated with an SFC system. However, investing in a good-quality system pays off in the long run. Consider the system’s durability and how well it can be upgraded later on.

2. Operating Costs

Include consumables, maintenance, and energy costs. Less solvent-demanding systems lower operational costs. Saving time and labor might also help reduce operational costs efficiently.

3. Environmental Impact

SFC comes with a reputation for being relatively eco-friendly. It consumes minimal organic solvent, which lessens the waste output. Such practices pay dividends for the planet and can align with broader sustainability goals.

Support and Training

1. Manufacturer Support

A dependable vendor provides great support. Find companies that provide extensive training and troubleshooting assistance whenever you need it. Good support helps you to minimize downtime and maximize productivity.

2. Training for Staff

When the operating system is implemented, proper training ensures that the staff working on the system knows how to operate it. Training programs can effectively facilitate the comprehension and resolution of some common problems. It results in improved outcomes and fewer operational problems.

3. Future-Proofing

Think about what your future needs and developments might be. A system that can be upgraded or expanded is going to have a longer shelf life. This versatility can lead to more bang for the buck over time.

Making the Decision

The selection of an appropriate preparative SFC system undoubtedly includes many considerations. The facility can then make informed decisions regarding what is best, given the lab’s unique requirements, technical requirements, cost, and long-term opportunities. A thoughtful selection process ensures the chosen system meets both current and future objectives.

Conclusion

Choosing a preparative SFC system is a big step for any lab. Once found, a system can help labs streamline their processes by concentrating on distinct demands, specifications, and future value. This decision influences efficiency and productivity and can also help promote a greener form of chromatography. With the right system, labs achieve fast and accurate separations for successful R&D.