Automation is changing the face of the electronics manufacturing industry, offering unparalleled opportunities for efficiency and innovation. Working to optimize operations, companies along the value chain of electronics are now understanding the transformative potential of automation and supply chain management tools. This article will delve into the key insights, benefits, challenges, and future prospects of automation in electronics manufacturing and provide valuable guidance for manufacturers, suppliers, and companies looking to implement electronics bom management software.

The Backbone of Modern Electronics Manufacturing: Key Insights

The production of electronic items is such a complicated process that it consists of several steps, from design to source. Every stage involves accuracy, speed, and coordination in order to respond to market challenges. In order to streamline the operating environment and achieve high productivity, this complex process mostly depends on automation.

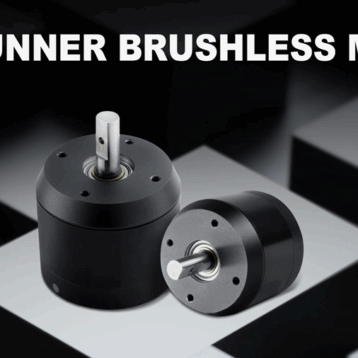

Robotics, AI, and machine learning are just a few of the technologies that use automation in electronics manufacturing. Manufacturers may increase quality control, decrease human error, and automate repetitive processes with the help of these technologies. By adding additional automation to the process, businesses may produce products that are more dependable and consistent.

Why Automation is the Missing Key to Efficient Operations

Automation is the missing key to efficient operations because it has redefined the whole process of performing, managing resources, and optimizing processes in the manufacturing of electronics. Automation can, in such scenarios, perform many of the repetitive activities with much less time and effort while assembling and making quality checks, reducing human error to a minimum, and increasing throughput. The advantage is that this not only hastens production but also frees up human operators, allowing them to concentrate their talents on strategic and problem-solving jobs.

Furthermore, it coordinates the value chain better due to its ability to provide real-time data and analytics that allow manufacturers to predict changes in demand and de-stock or build inventories based on it. This kind of precision ensures complete efficiency in resource use and minimizes losses arising from operational wastes. Besides, the agility of automation regarding any change in production needs or fluctuating market conditions allows manufacturers the flexibility to respond accordingly and maintain their competitive advantage. For businesses implementing automation tools like electronics BOM management software, these improvements are even more pronounced, as the ability to manage and optimize electronic components becomes a critical part of achieving streamlined operations.

In a way, automation causes the process not only to be effective and inexpensive but also agile while contributing to enhanced efficiency throughout the manufacturing process as a whole.

How Automation Powers Your Processes to New Heights

Automation provides electronics manufacturers with the power to take their processes to a new height by opening up more opportunities for flexibility and scalability. Businesses may swiftly adjust to market needs and grow their operations without compromising the quality of their products by implementing automated processes.

- Better Quality Control: Only high-quality items make it to market thanks to automated inspection systems, which are more accurate than manual inspections in identifying flaws and irregularities.

- Smarter cooperation: To promote innovation and shorten time-to-market, automation enables efficient design-to-source communication and cooperation with multiple stakeholders.

- Data-Informed Decision Making: Automatic systems create volumes of data that can be analyzed for trends, processes, and optimization and make better decisions based on that.

Overcoming the Hurdles of Automation Implementation

While the advantages of automation are pretty clear, there are also challenges in implementing these technologies. Companies may not fancy the many changes, high implementation costs, and technical complexities that come with automation. But these obstacles can be overcomed with proper planning and investment strategies.

It would be very wise for entrepreneurs to, first of all, identify exactly what part of their operation will benefit the most from automation. Deep analysis of ongoing processes may identify inefficiencies that could suggest what a good custom automation approach would be. Employee training and investments in change management might be other means to make the transition and integration of people with automated systems smooth.

What’s on the Horizon: The Future of Automation in Electronics?

With continuous development in technologies, the future of automation in electronics manufacturing will continue to push advance. This includes some emerging trends such as the Internet of Things, 5G connectivity, and advanced robotics, which is going to drive automation capabilities even more.

As these technologies continue to evolve, even more integration and connectivity can be expected from the manufacturers. That means smarter factories where machines communicate with each other and optimize production in real time. Additionally, predictive maintenance and self-optimizing systems enabled by artificial intelligence will be able to minimize downtime and boost efficiency.

In Conclusion

Automation isn’t a facade but rather a core necessity for change in the way electronics manufacturing operates. With automation, businesses can look to higher levels of efficiency, quality, and innovation. Automation is required to keep up and stay competitive in this ever-evolving industry.

Luminovo is at the helm of this transformation, making available solutions that allow business enterprises to realize the full value proposition of automation. Such advanced technologies, along with efficient supply chain management tools, will help companies smoothen their operations to gain a competitive advantage.

Share your thoughts and experiences with automation in electronics manufacturing in the comments. How has it impacted your business? What challenges have you faced, and how have you overcome them?