Improving warehouse efficiency is crucial for businesses aiming to enhance productivity, reduce costs, and improve customer satisfaction. A well-organized and efficient warehouse can be a significant competitive advantage, ensuring that products are stored, managed, and shipped in a timely and accurate manner. In this article, we will explore the top five strategies to boost warehouse efficiency, helping you streamline operations and optimize performance.

1. Implement Advanced Warehouse Management Systems (WMS)

One of the most effective ways to improve warehouse efficiency is by implementing a robust Warehouse Management System (WMS). A WMS is a software application that helps manage and control daily warehouse operations, including inventory tracking, order fulfillment, and shipping.

By automating key processes, a WMS can significantly reduce human error, improve accuracy, and enhance overall operational efficiency. It provides real-time data on inventory levels, which helps in making informed decisions about stock replenishment and order processing. Furthermore, a WMS facilitates better labor management by optimizing workforce allocation based on demand and workload.

When selecting a WMS, consider a system that integrates seamlessly with your existing Enterprise Resource Planning (ERP) software and other tools. This integration ensures that all parts of your supply chain are synchronized, providing a unified view of operations and improving decision-making processes.

2. Optimize Warehouse Layout and Design

The physical setup of your warehouse plays a critical role in its efficiency. An optimized warehouse layout can reduce travel time, improve workflow, and ensure the safety of employees. Here are some key considerations for optimizing your warehouse layout:

–Zoning:Divide your warehouse into zones based on product categories, picking frequency, or other relevant criteria. This approach helps in organizing inventory logically, making it easier for workers to locate items quickly.

–Flow:Design your warehouse layout to support a smooth flow of goods from receiving to shipping. Minimize bottlenecks and ensure that aisles are wide enough to accommodate equipment and personnel.

–Accessibility:Ensure that high-demand items are easily accessible to reduce picking time. Consider implementing vertical storage solutions, such as those offered by modula.us, to maximize space utilization and improve accessibility to products stored at different heights.

–Safety:Prioritize safety in your warehouse design by clearly marking aisles, exits, and hazardous areas. Implement safety protocols and provide regular training to employees to prevent accidents and injuries.

3. Implement Lean Warehousing Practices

Lean warehousing practices focus on eliminating waste and improving efficiency in warehouse operations. By adopting lean principles, you can streamline processes, reduce costs, and improve service levels. Here are some lean warehousing strategies to consider:

–5S Methodology:Implement the 5S methodology (Sort, Set in Order, Shine, Standardize, Sustain) to organize and maintain a clean and efficient warehouse environment. This approach helps in reducing clutter, improving organization, and enhancing productivity.

–Continuous Improvement:Encourage a culture of continuous improvement by regularly reviewing processes and identifying areas for enhancement. Solicit feedback from employees and involve them in problem-solving initiatives to foster a sense of ownership and engagement.

–Just-in-Time (JIT) Inventory:Adopt JIT inventory practices to reduce excess stock and minimize storage costs. By aligning inventory levels with actual demand, you can improve cash flow and reduce the risk of obsolescence.

4. Leverage Technology and Automation

Technology and automation play a vital role in transforming warehouse operations. By leveraging the latest advancements, you can significantly enhance efficiency and accuracy. Here are some technologies to consider:

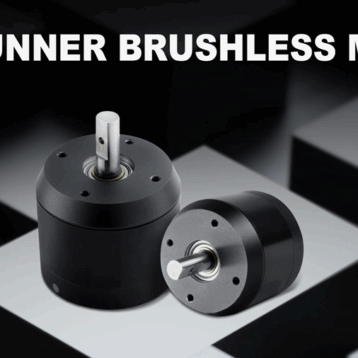

–Automated Storage and Retrieval Systems (AS/RS):AS/RS systems automate the storage and retrieval of products, reducing the need for manual labor and minimizing errors. These systems can handle a large volume of transactions with high precision, improving overall throughput.

–Barcode and RFID Technology:Implement barcode and RFID technology for accurate inventory tracking and management. These technologies enable real-time visibility of inventory levels, reducing the likelihood of stockouts or overstocking.

–Robotics and Drones:Consider using robotics and drones to automate repetitive tasks such as picking, packing, and inventory checks. These technologies can increase speed and efficiency while reducing labor costs.

–Data Analytics:Utilize data analytics to gain insights into warehouse operations and identify trends and patterns. By analyzing data, you can optimize processes, forecast demand, and improve decision-making.

5. Enhance Employee Training and Engagement

A well-trained and motivated workforce is essential for maintaining warehouse efficiency. Investing in employee training and engagement can lead to higher productivity, improved accuracy, and increased job satisfaction. Here are some strategies to enhance employee performance:

–Comprehensive Training Programs:Provide comprehensive training programs for new hires and ongoing training for existing employees. Ensure that workers are well-versed in operating equipment, handling inventory, and following safety protocols.

–Cross-Training:Implement cross-training programs to develop a versatile workforce capable of handling multiple tasks. Cross-training improves flexibility and ensures that operations continue smoothly, even in the absence of key personnel.

–Incentive Programs:Introduce incentive programs to reward employees for meeting performance targets and demonstrating exceptional skills. Incentives can include bonuses, recognition, or career advancement opportunities.

–Open Communication:Foster open communication between management and employees to address concerns, share feedback, and discuss improvement opportunities. Encourage a collaborative work environment where employees feel valued and motivated to contribute to the organization’s success.

In conclusion, improving warehouse efficiency requires a strategic approach that combines technology, process optimization, and employee engagement. By implementing advanced warehouse management systems, optimizing layout and design, adopting lean warehousing practices, leveraging technology and automation, and enhancing employee training and engagement, you can create a more efficient and productive warehouse environment. Embrace these strategies to stay competitive in the fast-paced world of logistics and supply chain management.