Photo by Mads Thomsen from Pexels

Identifying the Problem

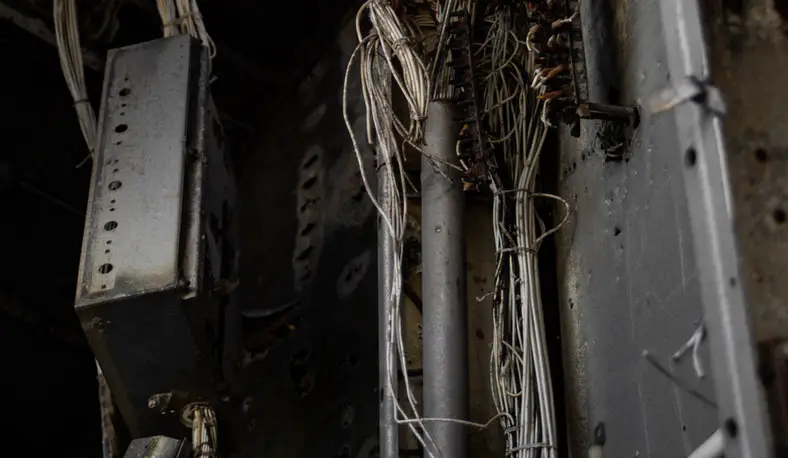

Over the course of the last 50 years, paper-insulated lead covered cables – widely known as PILCs – were frequently fitted in cities to provide electricity over the entire urban area. It was the case in Glasgow, in Scotland. This included 275 kV PILCs with gas compression fittings.

When the utility, SP Energy Networks, came up with a strategic schedule of investment which was designed to improve the network, a way of dealing with some of the legacy PILCs needed to be found. Their program aimed to roll out a new system for repairing faults with a new solution.

Overall, the challenge was to provide electrical energy supply without disruption as sections of cables were upgraded. This program meant the need to address one of the last 275 kV degassed circuits in operation on the network. Since this PILC was a crucial inter-connector, SP Energy Networks collaborated with experts at TE Connectivity. The job of the experts was to find a newly engineered solution that would allow the connection of contemporary polymeric cables to the old paper-insulated lead covered cables within a short time frame.

Coming Up With a Solution

SP Energy Networks gave TE Connectivity the challenge of devising a custom solution within three months. The knowledgeable electrical component engineers at TE set about coming up with an innovative cable joint to do the job. Ideally, the joint would be able to transition between the legacy PILC cables and the modern ones in a seamless manner. A sample of the cable was given to the engineers to study. Even though the PILC sample had received a rating of 275 kV, it had subsequently received a de-rating of 33 kV, largely because it had been de-gassed. This factor helped the engineering team in their search for a solution. However, the PILC was still of the same diameter as a normal 275 kV line. Crucially, the customized joint had to be capable of transitioning the wider, but now de-rated PILC cable, and attaching it securely to a regular polymeric cable, measuring only 630 square mm.

The solution that TE’s team came up with was only possible due to the high level of knowledge of those working on it and their ability to access a broad portfolio of products within the company. By making extensive use of the full range of components – including high voltage connectors and fittings which could be customized in shape and design – a bespoke joint was developed.

Indeed, the approach meant that TE’s Raychem heat shrink tubing, high voltage connectors, 72-kV plastic molded insulation and safe earthing equipment were deployed in the new joint.

After the design concept of the cable joint was decided upon, the team at TE collaborated with SP Energy Networks. Both their engineers and jointers were able to make their own assessment of the solution and to carry out as much testing as they thought appropriate at TE’s test center. Once the reliability of the joint had been established, a full set of test reports were generated for the client to oversee. Subsequently, TE’s team wrote detailed instructions for SP Energy Networks to help with the installation process. This was backed up with installation training sessions for the jointing personnel, to ensure a proper end installation of the innovative cable joint. Twenty five sections of tailored cable joint were ordered by the client.

A Favourable Outcome

A totally customized solution for the fault repair problems SP Energy Networks faced was innovated by TE within a very short time period. The solution was designed, configured and extensively tested within only three months. The jointer training was also completed within the same timeframe, which was essential to reduce the risk of installation errors.

In the end, SP Energy Networks were able to fit a bespoke solution when power losses occurred with their legacy gas compression cables. This meant that transmission system stability was maintained with the electrical supply throughout Glasgow. Furthermore, the project allowed TE to showcase its engineering power in connecting today’s polymeric cables to legacy PILCs with an innovative and solution-based approach.