One of the major reasons that electric vehicles still haven’t gained widespread adoption is due to their (still) limited range. And part of this issue is related to the weight of the batteries; they may weigh up to 1,200 lbs (544 kgs). This means the vehicles travel lesser distances on a single charge. Making the batteries lighter in weight has been the subject of ongoing research.

Conventional battery

A conventional battery has three main components – a positive electrode (anode), a negative electrode (cathode) and an electrolyte. When it is charging, the anode emits lithium ions that travel through the crystal structure of the electrode and the electrolyte to the cathode, where they are stored. The speed of charging depends upon the speed of this process.

However, what hampers this speed is the battery material. Graphite, which is used for negative electrodes because of its high density and ready acceptance of positive ions, is the best material presently available. To overcome its limitations, researchers searched for new electrode materials that have smaller particles.

However, this has not been successful, since unwanted reactions of nanoparticles with the electrolyte prevents the creation of a practical battery. It not only doesn’t last long but is also expensive to manufacture. There was a need for a different approach in this regard.

Structural battery

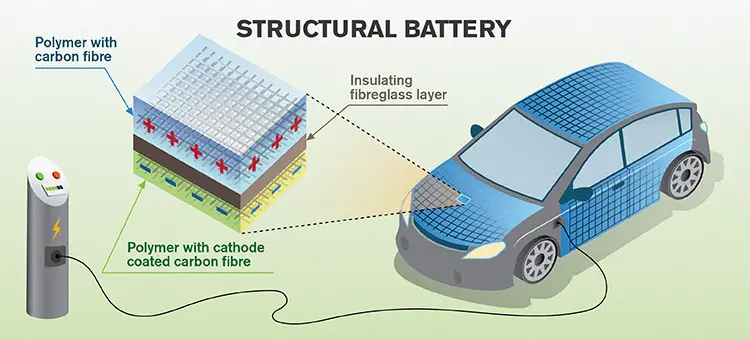

One breakthrough came from a study led by Chalmers University of Technology, Sweden. The researchers showed that carbon fibers, in addition to acting as a reinforcing material, can store energy directly by working as battery electrodes. In fact, carbon fiber becomes part of the energy system. This means that carbon fibers can be used to make ‘structural electrodes’, that is, the bodywork of vehicles and aircraft provide both structure and energy.

According to Professor Leif Aspof Material and Computational Mechanics at Chalmers University of Technology, a car’s body will no longer remain simply a load-bearing component, but will also act as a battery. This will help reduce the weight of a car or an aircraft by up to 50 percent. Not only this, but the carbon fiber can also be used for other purposes as well, such as for harnessing kinetic energy for sensors.

Benefits of carbon fiber for different industries

One of the main benefits of structural batteries is the decrease in weight. This, in turn, will lead to a substantial reduction in the weight of future vehicles and aircrafts using them. This will prove most beneficial to two main industries: automotive and aerospace.

- Car industry

The basic role of carbon fiber used in many vehicles is to make them lighter and stronger. However, the discovery of the ability of this ultra-strong material to store electricity directly and power a vehicle has potentially revolutionized the design of electric vehicles of the future. Once this technology becomes commercially viable and available, it may well replace the heavy batteries, thereby reducing the overall weights of such cars.

To be viable, the multifunctional carbon fibers need to attain a high energy storage capacity, in addition to sufficient stiffness. This breakthrough has now been achieved. Although carbon fibers with good electrochemical properties are slightly stiffer than steel, ones with poor electrochemical properties are twice as rigid. For electric vehicles, a slight reduction in rigidity is not a major issue. Since expensive carbon fiber composites are used in aircraft as per their stiffness, it can easily be extended to electric vehicle manufacturing too.

- Aerospace industry: The production of electric powered aircraft is no longer a pipedream. Until now, the major constraint for this was the weight factor. However, researchers are working with the aviation industry to explore the commercial application of carbon fiber technology to make electric airplanes a possibility.

For aircraft, increasing the thickness of carbon fiber composites may become necessary. This will compensate for the decreased stiffness of structural batteries. However, the gain would be increased energy storage capabilities. Furthermore, the reduced energy density of structural batteries will make them secure compared to standard batteries since they will not contain any volatile particles.

Conclusion

Perhaps the day is not far when structural batteries will become as prevalent as conventional batteries by virtue of their structural load-bearing ability. Carbon fiber technology is all set to revolutionize the car, aviation and related industries that use electric batteries.