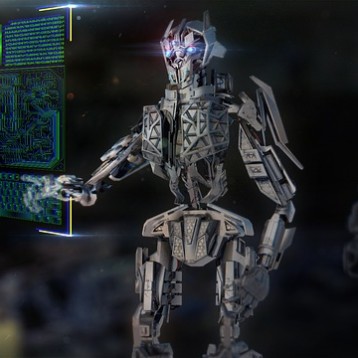

The arm is bolted to a cement floor and while at rest it’s about the height of an average adult. However, in just minutes it can extend to a radius of nine feet. In fact, during construction of the building in which the arm resides, ductwork above the arm had to be re-routed to avoid collisions. The arm rotates on six axes, and at its tip is a space for different endmills — similar to router blades on a shaft. The arm selects endmills from a tool changer near its base and uses them to cut away at any raw material the student selects. John Jacobson ARC ’70, the associate dean of the School of Architecture, said: “The agenda was to help our students; they’re able to create things they could never have created with conventional tools.”

Kuka HA 60-3 Automatic Super Arm

Yale School of Architecture is using an advanced robotic arm called Kuka HA 60-3 which is capable of multiple tasks as well as learning new actions. The robotic arm assists students to create 3D models in unprecedented precision and accuracy.

The arm is one of several different computer-numeric-controlled (CNC) machines architecture students can use to build models or final projects. It was purchased by the Yale School of Architecture in 2006 from Kuka Industries. The purchase of the arm and several other machines was made possible by a quarter-million-dollar anonymous donation in the spring of 2006; in addition, the software itself cost $50,000.

The Kuka HA 60-3 Automatic Scale Arm’s main advantage is its ability to learn and build in a matter of hours. When provided with a 3-D plan, the robot can cut away an identical model or final product from any given material. Its online manual, for example, shows students how it can carve a bust of Beethoven.

The beauty of the arm lies not only in its aesthetic elegance, but also in its capacity to create. Because it moves along six axes and can change endmills, the arm can cut away at objects with unparalleled precision. Its range of error falls within three to five thousandths of an inch. The arm is advantageous for students because it allows them to work on other projects as the arm is milling and also because it reduces human error. Still, students will still need to put on finishing touches themselves. “Machines are not going to finish a project to completion,” Joshua Rowley, an instructor and manager of the Fabrication Labs at the School of Architecture said. “It will still take the hand of the student to bring it to the final stage.”

The usage of the arm requires students both selecting the suitable material and choosing the right path for the arm to cut along. In addition, they need to ensure that all the machines move at the appropriate speed, so the material being used will not be damaged. Still, the arm itself features a number of safety measures. It can sense problems associated with heat, air pressure or resistance from the material. If it detects a problem, it will automatically shut itself off.

Even to an outside expert, the technology behind the arm and its use is impressive. Engineering professor Roman Kuc HON ’94, who specializes in robotics, praised the School of Architecture for using the arm in this way. “It’s exciting for students,” he said. “Now that they have the ability to design with 3-D tools, the extension of having a robot build the design removes some of the drudgery of building models.”

Architecture students have already begun to hone their skills with the arm. Ryan Welch ARC ’10, who works as a monitor in the Fabrication Lab, explains that the learning curve on the software for the different machines is steep. “When you first try [the software] out, it can be pretty daunting; but then you hit a threshold, and it opens up opportunities.”

TFOT has also covered the development of Mind Controlled Bionic Limbs, and the Soft House, a project by Kennedy & Violich Architecture which uses curtains and textiles for energy harvesting, electricity generating, and distributing materials. Other related TFOT stories include Festo’s Bionic Arm, created after a close study of the “design principles of nature,” and the Kitchen-Cleaning Robot.

For more information on the Kuka HA 60-3 Automatic Scale Arm, see Yale’s website.