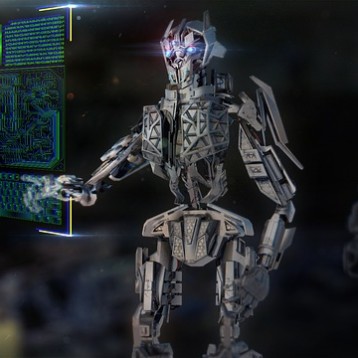

The landscape of manufacturing has undergone a significant transformation over the last few decades. As industries strive to enhance efficiency, accuracy, and safety, the integration of robotics into assembly lines has become a game changer. This article will explore the multifaceted role of manufacturing robots, the benefits they bring, the challenges faced during implementation, and the exciting future trends shaping this field.

The Role of Robots in Modern Manufacturing

Manufacturing robots have emerged as essential tools in today’s production environments. These advanced machines are designed to perform a variety of tasks, from assembly and welding to painting and packing. There are several types of manufacturing robots, each tailored for specific applications:

- Articulated robots: These robots resemble a human arm, featuring rotating joints that allow for complex movements. They are ideal for tasks requiring flexibility and precision.

- SCARA robots: Standing for Selective Compliance Assembly Robot Arm, these robots are perfect for tasks like assembly and packaging due to their ability to move in two horizontal directions.

- Collaborative robots (cobots): Unlike traditional industrial robots, cobots are designed to work alongside human operators. They are equipped with safety features that allow for safe interaction without the need for cages or barriers.

- Delta robots: Known for their speed and precision, delta robots are often used in high-speed packaging and assembly tasks, where rapid movement is crucial.

Robots in assembly lines enhance productivity through their ability to operate continuously, offering unmatched precision and consistency that human workers may struggle to achieve.

Benefits of Implementing Robots in Assembly Lines

The advantages of incorporating robots into assembly lines are substantial and wide-ranging:

Increased Productivity

One of the most significant benefits of manufacturing robots is their capacity to dramatically increase production rates. Robots can work around the clock, resulting in higher output without the need for breaks or downtime. This ability to operate 24/7 means that manufacturers can meet demand more efficiently.

Enhanced Product Quality

Robots excel in tasks that require high levels of precision and repeatability. By minimizing human error, they help maintain consistent product quality. For example, in automotive assembly, robots can ensure that components are fitted perfectly, reducing the likelihood of defects and recalls.

Cost Savings

While the initial investment in robotic systems may be substantial, the long-term savings often outweigh these costs. Robots can reduce labor costs significantly, and their efficiency can lead to a decrease in material waste. The automation of repetitive tasks allows companies to allocate human resources to more strategic roles, ultimately enhancing overall operational efficiency.

Improved Worker Safety

By taking on dangerous or strenuous tasks, robots enhance workplace safety. For instance, in manufacturing settings where heavy lifting is required or hazardous materials are present, robots can mitigate risks for human workers, leading to fewer workplace injuries and a safer overall environment.

Challenges and Considerations

Despite the numerous benefits, integrating robots into assembly lines is not without its challenges:

Initial Investment Costs

The upfront costs associated with purchasing and installing robotic systems can be a barrier for many companies. However, it’s crucial to consider the return on investment (ROI) that comes from increased efficiency and reduced labor costs over time.

Workforce Implications

One of the primary concerns surrounding the adoption of robotics is the potential for job displacement. However, rather than replacing human workers entirely, robots often take over repetitive tasks, allowing workers to engage in more skilled positions that require critical thinking and creativity. Upskilling and reskilling initiatives can help ease the transition for the workforce.

Integration with Existing Systems

Integrating robotic systems with legacy machinery can pose challenges. Companies need to ensure compatibility and consider how new software and control systems will interact with their existing processes. A thorough assessment and planning phase can help mitigate these issues.

Future Trends in Robotics and Assembly Lines

Companies like UR are pioneering advancements in artificial intelligence and machine learning, making robots smarter and more adaptive The future of robotics in manufacturing looks promising, driven by several emerging trends:

Advances in Artificial Intelligence and Machine Learning

As AI and machine learning technologies continue to evolve, robots are becoming smarter and more capable. These advancements will enable robots to learn from their environments, adapt to new tasks, and work more collaboratively with human operators.

Rise of Collaborative Robots

Collaborative robots (cobots) are expected to gain more traction as they become increasingly sophisticated. Their ability to work alongside humans without safety barriers makes them ideal for various applications, promoting a new era of human-robot collaboration.

Customization and On-Demand Manufacturing

As consumer preferences shift towards personalized products, the demand for flexible manufacturing processes is rising. Robots that can easily reprogram for different tasks will play a vital role in this customization trend, allowing manufacturers to respond quickly to market changes.

Sustainability and Eco-Friendly Practices

The push for sustainable manufacturing practices is leading to innovations in robotics that focus on energy efficiency and waste reduction. Companies are increasingly seeking robotic solutions that not only enhance productivity but also align with their sustainability goals.

Conclusion

Manufacturing robots are revolutionizing assembly lines, driving significant improvements in productivity, quality, and safety. As industries continue to embrace this technology, the potential for further advancements is vast. Companies like UR are at the forefront of this revolution, providing cutting-edge robotic solutions that enable manufacturers to thrive in a competitive landscape. By understanding and leveraging the capabilities of robotics, businesses can position themselves for future success in an ever-evolving market. The future of manufacturing is here, and it is powered by robots.