The scientists outlined their breakthrough in the Proceedings of the National Academy of Sciences (PNAS), which has already been published online. Earlier this year, the same team has published a paper in the journal Nature, which described new strategies for creating the liquid-metal composites. However, the alloys that were presented there were less than perfect – since the scientists intend to apply these materials specifically to aerospace applications, the composites are required to have very low densities, ideally in or around those of crystalline titanium alloys, which fall between 4.5 and 5 grams per cubic centimeter (g/cc). The original alloys, however, which were made predominantly out of zirconium, fell between 5.6 and 6.4 g/cc, making them practically unusable for any aerospace application.

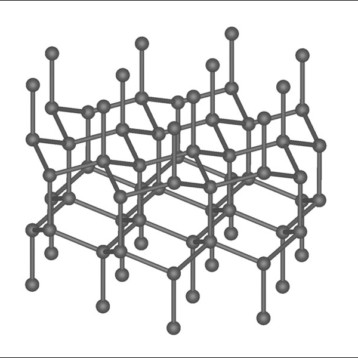

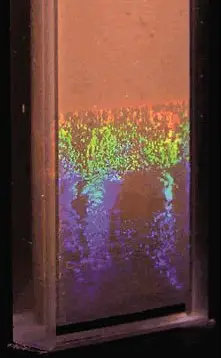

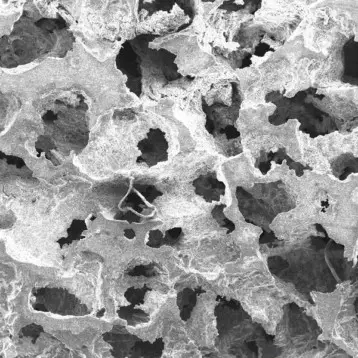

The researchers have eventually discovered that ductility is linked to the formation of branching; crystalline structures called dendrites within the metallic glass. By experimenting first with the size of the dendrites, Hofmann and his colleagues noted that when metallic glasses were bent, 10-nanometer-wide features called shear bands rip right through glass that is thicker than one millimeter, but are stabilized in thin glass. “The bending experiments told us that the size of the particles we need to add is proportional to the length scale of the shear bands before they become catastrophic,” Hofmann describes.

The initial research led to the development of alloys with “unrivaled strength and toughness” according to Hoffman, who added that the new composites are “among the toughest engineering materials that currently exist.” Driven by the promising results, Hoffman and his colleagues – including William Johnson, Caltech’s Ruben F., and Donna Mettler, Professor of Engineering and Applied Science and a pioneer in the creation of metallic glass – set out to improve the alloys, and after tweaking the components in the composites came up with a titanium-rich composition that satisfactorily maintained the properties of previously created zirconium alloys.

The work detailed in the paper “Development of Tough, Low-Density Titanium-Based Bulk Metallic Glass Matrix Composites with Tensile Ductility,” was supported by the U.S. Office of Naval Research. Hofmann was supported by the U.S. Department of Defense through the National Defense Science and Engineering Graduate Fellowship program.

TFOT has previously covered a number of innovations in the field of material engineering, such as a plastic and metal composite conductive material recently developed by researchers at the Fraunhofer Institute for Manufacturing Technology and Applied Materials Research in Bremen, Germany. Be sure to also check out our coverage of nickel-manganese-gallium alloy foam, which changes shape when exposed to a magnetic field.