|

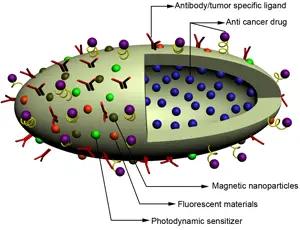

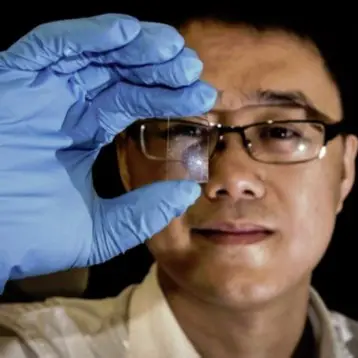

The new battery system, developed by Gary Rubloff and his team at the Maryland NanoCenter facility, is approximately ten times more efficient than anything currently commercially available, allowing for a tenfold increase in power density. It consists of millions of virtually identical nanostructures designed to store, carry, and deliver electrical energy. The system exploits various combinations of standard physical properties to achieve higher power, more storage, and rapid recharging.

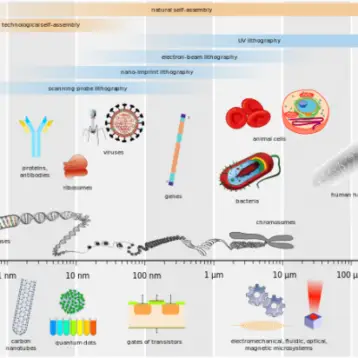

The nanocapacitor takes advantage of self-assembly, the process by which a collection of components reorders itself into a set pattern determined by local interactions between each item without direction from any outside forces. It also uses self-alignment, the process by which a collection of components reorders itself based on chemical composition and interactions as well as a self-limiting reaction which prevents the components from expanding beyond a well-defined physical area so that they remain within the confines of the group interactions.

The nanocapacitor can only take advantage of these physical properties because the individual components are so small and placed so close together. Pores 50 nanometers in diameter and 30 nanometers deep are etched into a glass plate covered with aluminum with 25 nanometer spacing. Exact, regular spacing is possible by carefully controlling the reaction conditions and taking advantage of the properties described above. A thin layer of metal, then a thin layer of insulator, then another thin layer of metal is deposited into each pore, mimicking the traditional electrode-insulator-electrode composition of normal electrostatic capacitors. The layer of aluminum on the glass plate serves as one electrical contact for the tiny capacitor elements; another layer of aluminum is placed on top of the pores to complete the capacitor. The full capacitor looks a lot like a solar panel and can be layered to increase capacity even further.

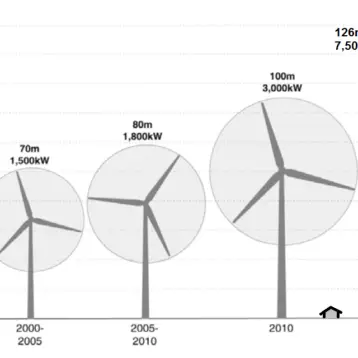

Rubloff and his team see many practical uses for the nanocapacitors once it becomes possible to manufacture these at larger sizes and in quantity. One of the primary problems they set out to solve was storage of energy gathered from alternative power sources. Many conventional storage devices do not have the capacity or cannot charge quickly enough to adequately capture power from large wind turbines or extensive solar power installations. The new nanocapacitors could collect this power much more efficiently than according to current methods, and redistributed to discharge the energy into capacitor-powered cars or factories or homes.

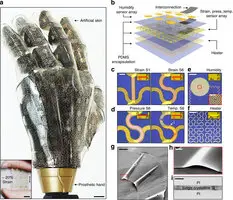

TFOT has previously reported on the use of a carbon graphene layer to store power in a similar nanocapacitor. We have also reported on other capacitor-based power storage technology including a rapidly recharging flashlight incorporating capacitors instead of batteries, a ferroelectric polymer capacitor capable of delivering power very quickly, and a micro-battery powered by viruses with a design based in part on the standard electrostatic capacitor.

Read more about the new nanocapacitor storage mechanisms in this University of Maryland press release.

Icon image credit: Wikimedia Commons user Friedrich1997