Lost inventory, slow updates, and wasted stock-these problems hurt businesses every day. But technology is changing the game. Smart systems now track, update, and manage inventory in real time, saving time and money.

Let’s dive into how technology is making inventory control faster, easier, and more efficient!

The Shift to Automated Inventory Tracking

Automated inventory tracking has made managing product inventory faster and more accurate. Businesses no longer need to rely on manual counts, which can lead to mistakes and wasted time.

With digital tools like barcode scanners and RFID systems, product inventory updates in real time. This helps companies avoid stock shortages and overstocking issues. Automation makes inventory control easier, saving businesses time and money.

Real-Time Data for Better Decision-Making

Real-time data helps businesses make better decisions by providing up-to-date inventory information. It allows companies to track stock levels, sales trends, and demand instantly.

With accurate data, businesses can restock products at the right time and avoid shortages. It also helps reduce waste by preventing overordering. Real-time insights make inventory management more efficient and cost-effective.

Cloud-Based Solutions for Easy Access

Cloud-based solutions make inventory management easier by allowing access from anywhere. Businesses can check stock levels, update records, and track shipments in real time.

This helps teams stay connected and make quick decisions without being in the same location. Cloud systems also offer automatic updates and secure data storage. Using cloud technology makes inventory control more flexible and efficient.

AI and Machine Learning in Inventory Management

AI and machine learning help businesses manage inventory more efficiently. These technologies analyze sales patterns to predict demand and avoid stock shortages.

They also automate restocking by tracking which products sell the fastest. AI reduces human errors and improves accuracy in inventory control. With smarter inventory management, businesses save time and money.

The Impact of IoT on Stock Control

The Internet of Things (IoT) makes stock control more accurate and efficient. Smart sensors track inventory levels in real time and send automatic updates. This helps businesses avoid running out of stock or overordering.

IoT also improves warehouse management by reducing errors and speeding up operations. With better tracking, companies can save money and keep customers happy.

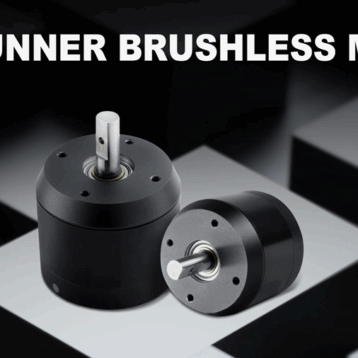

Barcode and RFID Technology for Accuracy

Barcode and RFID technology help make inventory tracking more accurate and efficient. Barcodes allow quick scanning of products, reducing manual errors. RFID tags use wireless signals to track multiple items at once, saving time.

These technologies improve product organization and speed up stock counting. With better accuracy, businesses can manage inventory smoothly and avoid shortages.

Reducing Waste and Improving Efficiency

Reducing waste and improving efficiency help businesses save money and resources. Automated inventory systems prevent overstocking and product spoilage.

Better tracking ensures that items are used before they expire or become outdated. Streamlining processes reduces delays and improves workflow. When waste is minimized, operations run smoothly, and profits increase.

Learn All About Inventory Control Systems

Technology has made inventory control faster, smarter, and more efficient. Automation, real-time tracking, and AI help businesses reduce waste and avoid stock issues.

Cloud and IoT solutions keep inventory updated and accessible from anywhere. Barcode and RFID technology improve accuracy and save time. With the right tools, managing inventory becomes easier and more cost-effective.

Visit our blog for more!