Automation is becoming an indispensable part of pharmaceutical companies to make the work less cumbersome. For example, a recombinant protein expression company or a pharmaceutical packaging enterprise can use automation to make repetitive tasks accomplished at a better speed.

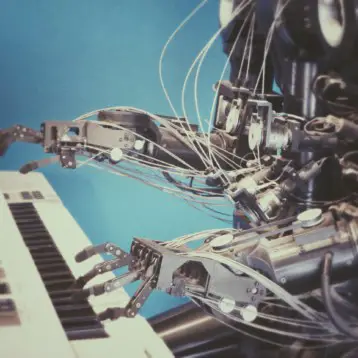

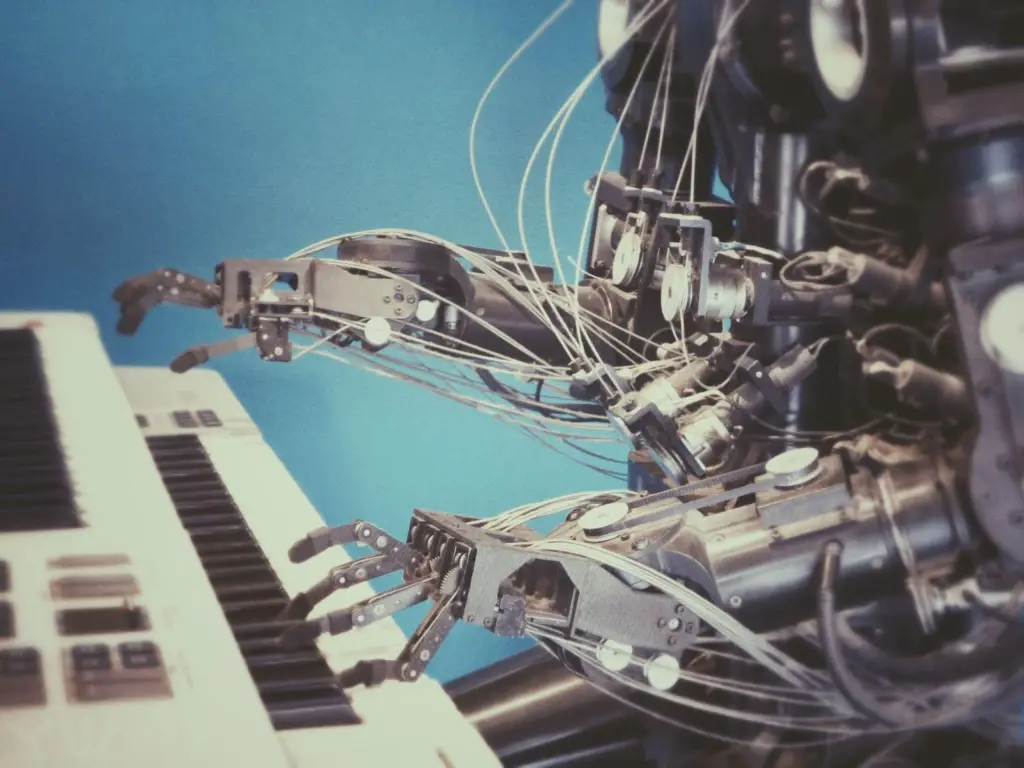

Benefits of Robotization:

The first question that needs answering is “Why replace human labor with robots and automation?” To answer this question, let’s look at some benefits of robotics

- Robots can increase productivity by accomplishing tasks faster.

- Robots perform a task in the same way which ensures the consistency of the product.

- Robots can work 24 hours a day and 7 days a week.

- Robots are easy to program.

- Robots can help with trials making the work of the R&D department better and more efficient.

Applications of Robots:

Robots can be used in the following pharmaceutical areas.

- Filling and Packaging:

Robotic technology is used in filling the vials. It includes transferring the components from station to station, both before and after filling and packaging. Another ideal application for robotics is automated assembly, inspection, and packaging of syringes. Automatic inspection has the advantage of enabling hundred-part inspection. Vision-sensing technology is used to verify the serial numbers of the products to ensure track and trace regulations. Advanced vision sensors can differentiate colors which allow machines to differentiate between different bottle cap colors.

- Personalized Medicines:

The automation company Invetech partnered with a biopharmaceutical company to program automated systems for personalized immunotherapies. It is based on Argos Arcelis technology which uses two robot arms for producing mRNA from a patient’s tumor which is then used for devising personalized medicine. The dendritic cells are developed from white blood cells via automated manipulation. Dendritic cells express the required antigen which is used in therapy.

Clinical processes are skill-based and time-taking which makes them difficult to be operated on a commercial scale with cost-effectiveness. The use of robotics and automation however makes it easier to develop therapies on a commercial scale efficiently.

- Cleanroom Robots:

The best application of robotics is in aseptic filling and other sterile processes because it eliminates the risk of contamination via humans. Robots ensure an ISO 5 environment to prevent microbial contamination as well. The Fanuc robots can also withstand hydrogen peroxide sterilization and are waterproof. Robots used in cleanrooms should be programmed to minimize the generation of particulate matter. The robot should be resistant to all the sterilization material and cleaning materials used in the laboratory. Controlling the speed of robots to ensure the maintenance optimum environment in the laboratory is also important.

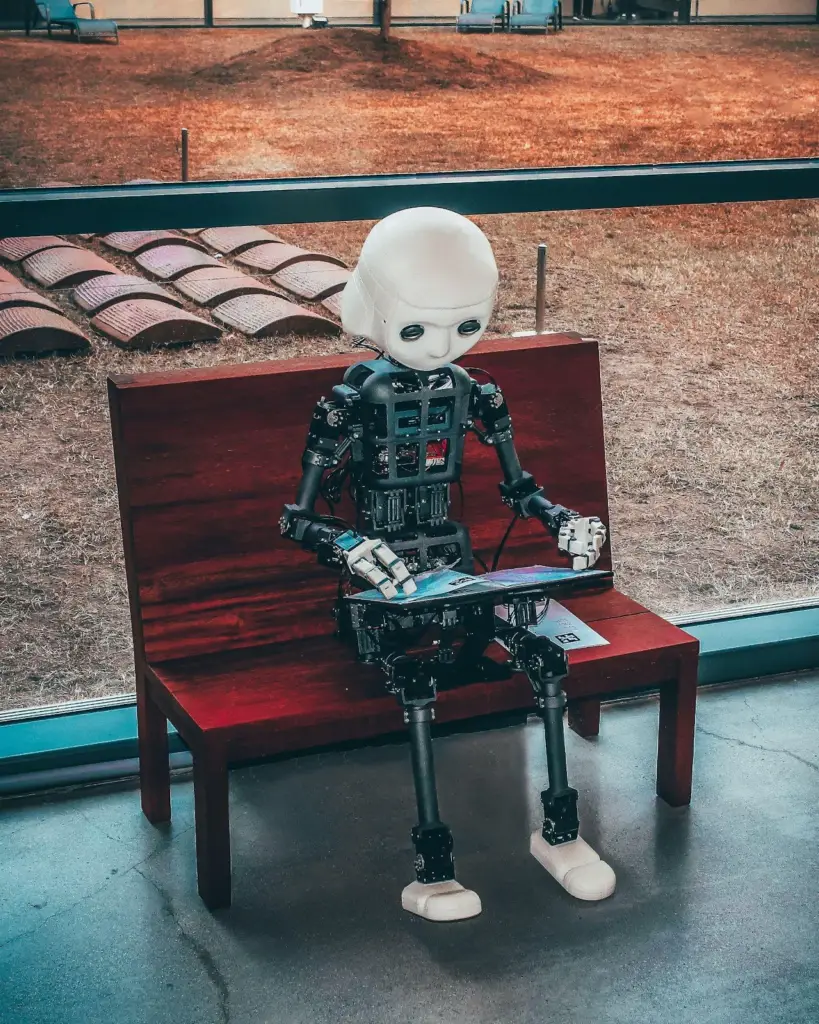

- Lab Robotics:

In labs, robotics is used in loading the instruments. For example, transferring microtiter plates between instruments. Although it can be done manually, programmed software doing the job reduces human error, maintains the quality of the experiment, and allows scientists to focus on content instead of execution.

Robots are also in vial handling in laboratories. For example, a Fanuc robot was designed to include a handling hand that can hold almost ten vials at the same time. Other instruments like an index table for handling stacks, a thermostatically controlled water bath, a retrieval system for vials, and a preservative spray station were also included in the robot.

Similarly, the Jiko infusion machine is useful in this context because it is more accurate and effective than a human, ensuring precise infusion without the risk of errors, thus maintaining high standards of quality and efficiency in the field of medical marijuana.