Prototyping machining is a procedure brought up to noticeably cut down on the time it will take to build a site since the designer just builds up the prototype made.

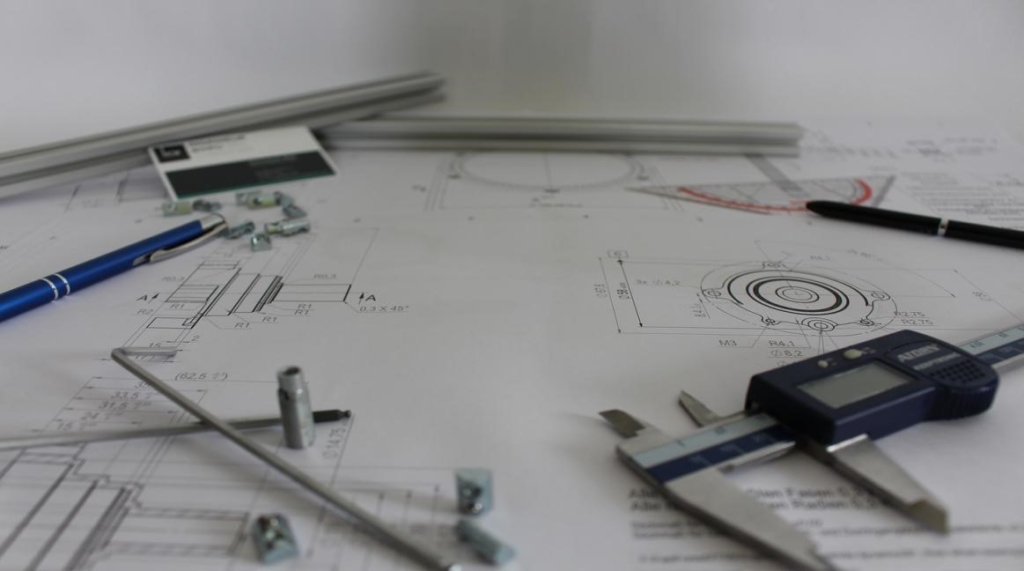

Although a prototype has been conceived to be a blueprint, an early sample or mock-up is designed to test-run a procedure, a process, or even an idea. It is also a miniaturized plan or design set-up to determine what course a particular idea or design will follow.

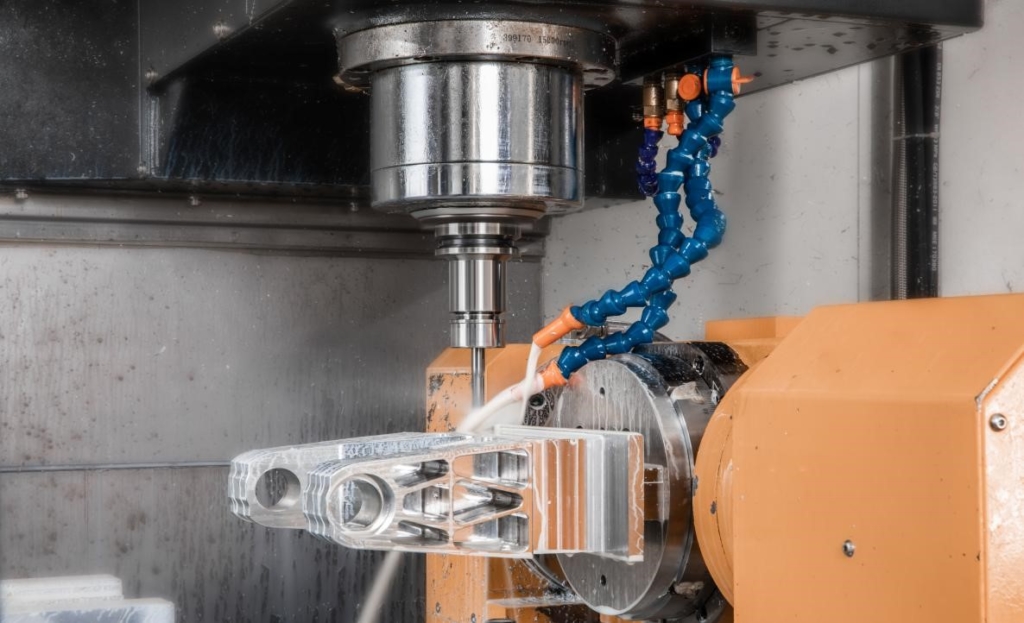

Nevertheless, custom CNC machining is a one of quick prototyping model giving us a clue about the real plans for the finished product. Prototypes can be simple sketches about the product we wish to build. These are referred to as “lo-fi” while the “hi-fi” ones are the real working models which the end-users can touch and make use of.

Moreso, for enterprises and large-scale businesses, prototyping is important because it helps to test samples before producing in bulk. This will reduce wastage in case an error is needed to be fixed in the model built.

Factors Affecting The Cost of Custom CNC Prototype Machining

Finding out what it will cost to design a custom prototype for CNC machining can be very herculean as a result of the several factors involved. While there are myriads of factors affecting the cost of the prototype, some of these factors are key contributors which could be used to make logical estimates. Let’s quickly take a look at the cost of physically producing and constructing the parts.

Material

The type of material a designer is using to fabricate his parts is one of the greatest factors which determines the overall process cost. Certain materials like engineering plastics are usually less costly when compared to materials like steel. Metals also have costs as the constituents vary from each other.

How thick a material is will play a key role in determining the cost of that material. It will also influence the cost of labor that will be needed. It is essential to select just the right material that meets the project requirements. However, if multiple materials are needed to satisfy the requirement, the cost is a key factor to consider. Materials made from metals are usually priced by extrinsic market factors, although they aren’t usually very volatile.

Design

Most certainly, the size and design of the CNC prototype are equally key factors to consider in the cost of CNC machining prototyping. Larger parts will consume a lot of materials in the manufacturing process. The processing cost increases as the size and build of the machining get complex.

Design parts that need precision and accuracy, long-range machine, improved surface finish, or complex geometry are costlier than the simple ones. As such, anytime designers make prototype sketches according to the plan, the structure should be simplified to the best. One should consult an expert CNC custom prototype designer before decisions are taken.

Prototype Methods

There exist various methods of making prototypes. Just as earlier mentioned, it could range from the lo-fi such as simple sketches to the hi-fi which are more realistic since the users could feel and touch the real thing. The prototype method adopted depends on the product the designer intends. It could be about CNC machining, sheet metal, injection molding, 3d print, the cost of these methods varies from one another.

Tolerances

Yet another important factor that affects the cost of CNC prototyping is tolerance. That is, the level of precision we want for the prototype. CNC machining ranks as one of the manufacturing procedures that demands a high level of precision today. However, this does not imply that a particular part will always need high precision. When part tolerances get very tight, the cost of the CNC machining process goes up too. This is because it takes a lot of time to attain high precision levels.

What it costs for a CNC machining can go double when a tolerance level varies between ±0.030 and a standard tolerance of ±0.005. If we are to consider a tolerance level of ±0.001, then, we may be looking at an increase that could quadruple the original cost of production. It is very important, therefore, that we ascertain the level of precision needed for the prototype we want to build, so we can cut back on the cost.

Tips For Reducing the Cost of Custom Prototype

Now that we have analyzed all the costs that affect the CNC prototyping design, it is equally important that we make a list of some useful tips that can help in reducing the cost of the project.

Material Used

Many people don’t think about the material, especially starter-ups. Alloy is quite expensive for instance, but then, aluminum is much cheaper and easier to work on. Again, it is important to determine if special features such as high-temperature resistance would be needed and then choose the material accordingly.

Plastics could also be used in making prototypes. However, usually, the mould in that case would be made of a thermoset plastics. The strength of the plastic must also be properly analyzed.

Reduce manufacturing waste

Any form of wastage in the manufacturing procedures will cost you. The concept of lean manufacturing emphasizes the excision of the unneeded parts of production such as faulty parts, scrap materials, and industrial by-products.

Time-Consuming

The time consumed in manufacturing the product will have a significant effect on the overall cost of the project. Projects that take long years to complete will cost more than projects that took just a few days.

Avoid complex surfaces

Peradventure you want a fast prototyping, complex surfaces with impressive smoothness should not be considered. This is because it will cost you time and more effort to achieve than the regular surface.

Conclusion

Computer Numerical Control (CNC) is an innovative approach to manufacturing where computer codes are used to program and operate manufacturing tools. It makes manufacturing more efficient and the products come out with greater precision. A CNC machining prototype is, however, necessary before large-scale production is embarked upon.

Prototyping ensures that the interest of the client is well captured in the design process as they get to partake in the work, making the process more consistent. By the use of prototyping inventions can easily be brought to reality once they are prototyped. It helps them to analyze the technical feasibility of the project. It enhances the project’s quality and ensures that the end result is clearly represented.

Prototyping a project helps in reducing risks. When a design is made for a project, the most important components of such a project such as finance, time, materials are affected. Prototyping will reveal the obscure shortcomings and functional deficiencies that are identified and corrected.

There are many CNC machining prototype design companies. One of such experts is RapidDirect CNC machining prototype. They build designs of a project’s prototype with high precision and instant quotes platform that clients can easily relate with.