|

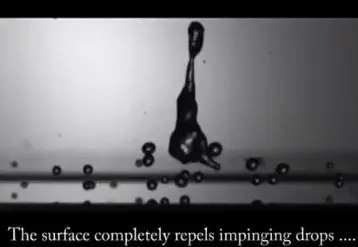

Traditionally, superhydrophobic coatings were expensive, ineffective, or not durable enough to be practical. Because they are difficult and expensive to produce, high quality superhydrophobic materials are generally used only in university research laboratories. It is unprofitable to produce these materials in large volumes, and it is extremely difficult to produce a commercially viable water-repelling coating. Simpson’s new nano-structured material is designed so that even when it is submerged in water, the material is covered by a microscopic layer of air. This design causes a profound change in the basic water-solid interface, resulting in an effect which Simpson likes to call the “Moses effect.”

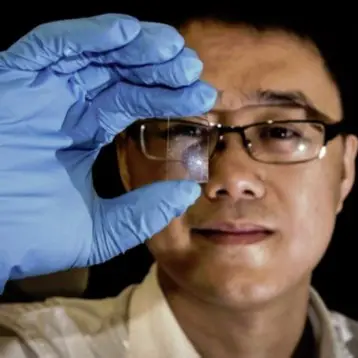

Simpson’s superhydrophobic material is glass powder. The powder is produced by differentially etching two glass phases from phase-separated glass. After separating glass as the base material, the material is heated up to separate it further. It is then crushed and turned into powder, which is then differentially etched to completely remove the interconnected borate glass phase. Differential etching makes the powder porous and creates nanoscale sharpened features. Finally, the powder is treated with a special hydrophobic solution to change the glass surface chemistry from hydrophilic to hydrophobic. The powder’s porosity and nanoscale sharpened features amplify the water’s surface tension effect and causes the powder to become “un-wettable.”

|

This superhydrophobic powder has many features and advantages, some of which include ease of manufacturing, low production costs and scalability. Only a small amount of inexpensive superhydrophobic powder is needed to coat a relatively large surface area. Another advantage of this powder is that because it traps air, it can act as a thermal and electrical insulator. The layer of air between the coated substrate and any water on the surface could greatly reduce and may even entirely prevent water-based corrosion. Simpson believes that as more people become aware of his technology, the number of possible applications will continue to grow.

Last year, TFOT covered MIT’s ‘HolyBot’ – a unique robot inspired by the movement of water striders (insects that can run across the surface of water), which can move on the surface of water and other fluids. TFOT also covered new micro-sensors designed for on-site detections of air and water pollution. More recently, TFOT covered an MIT research project that led to the design of a new class of material structures, which can repel oils.

More on Simpson’s superhydrophobic material can be found on the Oak Ridge National Laboratory website.