In industries where environmental challenges are a daily reality, robust IT hardware is a necessity—not a luxury. From cleanrooms to hazardous manufacturing floors, the demand for durable, high-performance systems is growing globally. Companies operating in such conditions require technology solutions that excel under extreme pressure while ensuring seamless productivity.

Meeting the Needs of Harsh Environments

Unlike standard office IT equipment, hardware designed for demanding environments must endure a range of challenges, including dust, humidity, temperature fluctuations, and corrosive substances. Industries like pharmaceuticals, food production, chemicals, and electronics assembly operate in controlled spaces where precision and reliability are critical.

For example, cleanroom IT systems are essential in sectors where airborne particles can compromise production. Cleanrooms, which meet stringent standards for air quality, demand IT hardware that does not emit contaminants while resisting the surrounding environmental stresses. This specialized hardware integrates features like fanless designs, hermetically sealed casings, and corrosion-resistant materials to maintain performance.

Durability and Innovation in Design

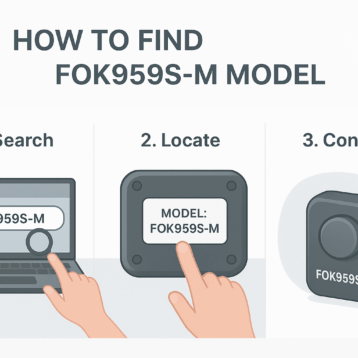

The most advanced hardware solutions combine rugged durability with innovative designs to deliver both performance and longevity. Key features include:

- Rugged Exteriors: Industrial IT hardware is typically housed in stainless steel, aluminum, or reinforced polymer enclosures. These materials protect against wear and tear caused by harsh chemicals, vibrations, and moisture.

- Touch-Friendly Displays: Many environments require gloves during operations. Touchscreen IT systems built for such conditions feature high-sensitivity screens that respond to gloved input without compromising accuracy.

- Fanless Cooling Systems: Traditional cooling systems often fail in challenging environments due to particle build-up. Fanless, sealed systems ensure dust-free operation while regulating internal temperatures.

- Water and Dust Resistance: Devices with IP65 or IP69K certifications guarantee protection against water jets, dust particles, and other contaminants, making them ideal for wet or dusty industrial spaces.

For international enterprises, standardization of hardware ensures scalability. Manufacturers like Blue Line excel at developing IT solutions tailored for harsh industries, ensuring compliance with global certifications.

Applications of Cleanroom IT and Industrial Hardware

Cleanroom IT and industrial-grade hardware have numerous applications across critical industries:

- Pharmaceuticals: Sterile production environments require cleanroom-certified monitors, PCs, and operator panels that align with ISO cleanliness standards.

- Food Processing: Hygienic IT solutions withstand frequent cleaning cycles, often involving high-pressure water and sanitizing chemicals.

- Electronics Manufacturing: Dust and static sensitivity demand anti-contaminant hardware with precise operational control.

- Chemical Industries: Corrosion-resistant materials and sealed systems protect IT hardware from exposure to hazardous chemicals.

These applications underscore the critical role IT hardware plays in maintaining operational efficiency while adhering to environmental regulations.

Global Demand for Reliable IT Hardware

Across international markets, the push for reliable and robust IT solutions continues to grow. Organizations require versatile systems that meet both industry-specific challenges and universal safety standards. Investing in hardware that combines resilience, precision, and adaptability is vital to minimizing downtime and ensuring high-quality production.

The Future of Industrial IT Hardware

The evolution of industrial IT hardware is driven by advancements in automation, IoT, and artificial intelligence. In demanding environments, the need for systems that can integrate seamlessly with modern technologies while offering durability will only increase. Solutions like cleanroom IT are shaping industries that depend on both innovation and reliability, making them a cornerstone of global industrial success.

As industries continue to tackle complex challenges, IT hardware built for extreme environments will remain essential for productivity, efficiency, and growth worldwide.

![How to Reset Insignia TV [Step-By-Step Guide]](https://thefutureofthings.com/wp-content/uploads/2025/01/Insignia-Roku-TV-358x358.png)