When embarking on the journey of designing and producing electronic devices, selecting the right components is crucial to the success of your project. Whether you are a hobbyist working on a personal project or a company aiming for mass production, the components you choose will determine the performance, cost, and reliability of your final product. This article will guide you through the process of selecting the most appropriate electronic components to meet your production needs.

Understanding Your Requirements

The first step in choosing electronic components is to clearly define the requirements of your project. Begin by outlining the specifications and functions your final product must achieve. Consider factors such as the operating environment, expected lifespan, power consumption, and any size or weight constraints. Having a comprehensive understanding of these requirements will significantly narrow down your options and help you focus on components that meet your specific needs.

Research and Compatibility

Once you have a clear understanding of your requirements, conduct thorough research on available components. Look into datasheets, manufacturer specifications, and industry standards. It’s essential to ensure that the components you choose are compatible not only with each other but also with the design and architecture of your project.

For example, if you are designing a wearable device, you will need components that are small, lightweight, and energy-efficient. Investigating options like microcontrollers, sensors, and power management ICs that are specifically designed for low-power applications can lead you to the best choices.

Evaluating Quality and Reliability

In any production process, the quality and reliability of electronic components are paramount. Components that fail often or do not perform as expected can lead to costly recalls and damage to your brand’s reputation. Therefore, it is important to source components from reputable manufacturers known for their quality control and reliability.

Consider components that have been tested under conditions similar to your intended application. Look for certifications and compliance with industry standards, such as RoHS (Restriction of Hazardous Substances) or ISO certifications, which can be indicators of a component’s quality and reliability.

Cost Considerations

While it is tempting to choose the cheapest components available to reduce the overall production cost, this approach can backfire if those components compromise the quality or reliability of your product. It’s crucial to strike a balance between cost and quality. Conduct a cost-benefit analysis to determine the long-term value of investing in higher-quality components versus the potential costs associated with failures or underperformance.

Don’t forget to consider the total cost of ownership, which includes not only the purchase price but also factors such as availability, lead times, and potential costs associated with obsolescence.

Supplier Relationships and Availability

The supply chain is an integral part of production, and establishing strong relationships with reliable suppliers is vital. Choose suppliers who offer not only competitive pricing but also excellent customer service and support. Suppliers who are willing to work closely with you can provide valuable insights and assistance, especially during the design and prototyping phases.

Ensure that the components you choose are readily available and not subject to long lead times. This is particularly important if you plan on scaling up production, as any delays in component availability can disrupt your manufacturing schedule and lead to costly delays.

Future-Proofing Your Design

Technology is constantly evolving, and what is cutting-edge today may become obsolete tomorrow. Future-proofing your design involves selecting components that are not only suitable for your current needs but also adaptable to future advancements. Consider components that offer flexibility and scalability, allowing your design to be easily updated or modified as new technologies emerge.

Staying informed about industry trends and potential technological advancements can help you make informed decisions that extend the lifecycle of your product.

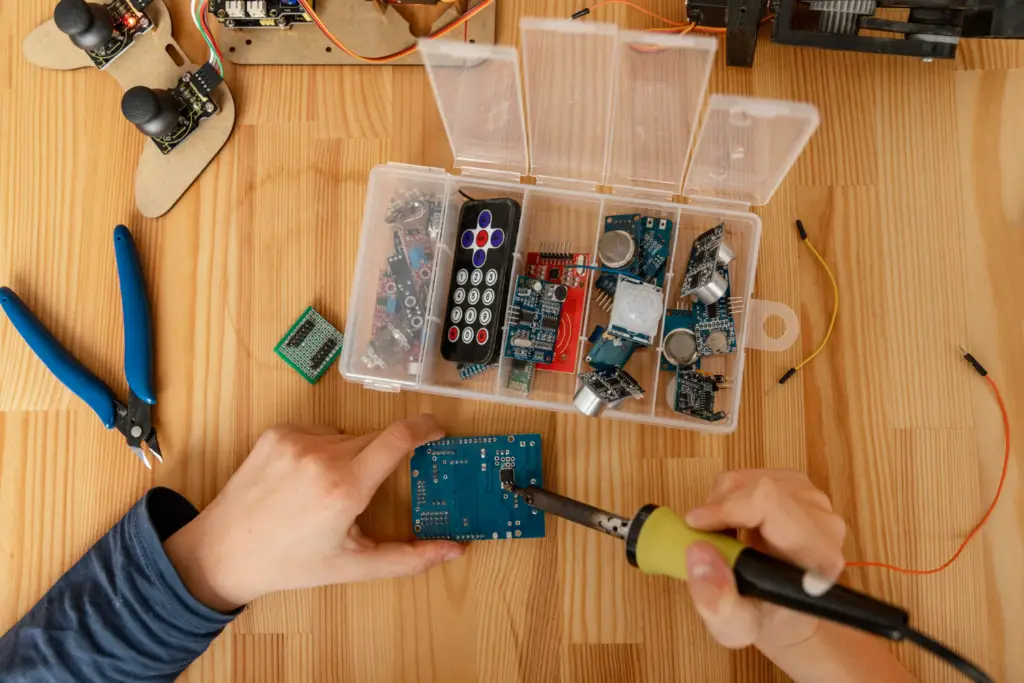

Testing and Prototyping

Before committing to full-scale production, it’s essential to thoroughly test and prototype your design. This stage allows you to identify any potential issues with the components you’ve selected and make necessary adjustments. Prototyping offers a hands-on opportunity to evaluate the performance, reliability, and integration of your chosen components within the complete system.

During testing, pay particular attention to how the components perform under various conditions, as this can reveal hidden issues that may not have been apparent during initial selection.

Documentation and Support

Adequate documentation and technical support from component manufacturers can significantly ease the design and production process. Look for components that come with comprehensive datasheets, application notes, and design guides. These resources can provide valuable insights into the optimal use and integration of components within your design.

Additionally, consider the level of technical support offered by the component manufacturers. Access to knowledgeable support teams can be invaluable, especially when troubleshooting issues or making design revisions.

Environmental and Regulatory Compliance

In today’s market, environmental and regulatory compliance is not only a legal obligation but also a key factor in consumer perception and brand reputation. Make sure the components you select comply with relevant environmental regulations and standards. This includes considerations for hazardous materials, energy efficiency, and waste management.

Being proactive in ensuring compliance can prevent legal issues and enhance your product’s appeal in environmentally conscious markets.

Conclusion

Selecting the right electronic components for your production needs is a multifaceted process that requires careful consideration of various factors. From understanding your project requirements to evaluating the quality, cost, and availability of components, each decision impacts the final outcome of your product.

By taking a strategic approach and leveraging industry resources, you can make informed decisions that enhance the performance, reliability, and marketability of your electronic products. Remember, the components you choose today lay the foundation for your product’s success tomorrow.

![How to Reset Insignia TV [Step-By-Step Guide]](https://thefutureofthings.com/wp-content/uploads/2025/01/Insignia-Roku-TV-358x358.png)