Slip rings are often an overlooked component of many engineered devices, and if you are new to engineering or you’ve just been taking apart an old electrical device, it’s most likely you’ve come across a slip ring.

Of course, slip rings have come a long way and even though there are only a couple different types – they’re being used in industries around the world.

In this article, you will find out everything there is about slip rings and their importance in the modern world nowadays. And by the time you finish with this article, you’ll be up to date with slip rings – no matter if you’re an engineer or just a curious individual. For more information about

Therefore, in this article, you will find the following:

- What is a slip ring?

- Main components of a slip ring

- How does a slip ring works?

- Why do we use slip rings in motors?

- What is the difference between the slip ring and split ring?

- Conclusion

What is a Slip Ring?

Figure 1: Standard Slip Ring

Image Source: DSTI

Slip ring is a device that is made to help transform power and the electrical signal from a stationary to a rotational part of the electrical device.

Since a slip ring has a pretty important yet versatile function, it can be used in any electromechanical device, no matter the industry or use.

The signal is always sent from a stationary part of the device to a rotational part – and you can think of a slip ring as a bridge between these two parts that connects them.

Therefore, it’s very common to see a slip ring is used in an electrical motor, AC generator, and plenty of other electromechanical devices which consist of both stationary & rotational part yet require the transmission of power and signal.

Don’t be surprised to find out slip rings are being used even in wind turbines to help take advantage of alternative energy resources.

Main Components of a Slip Ring

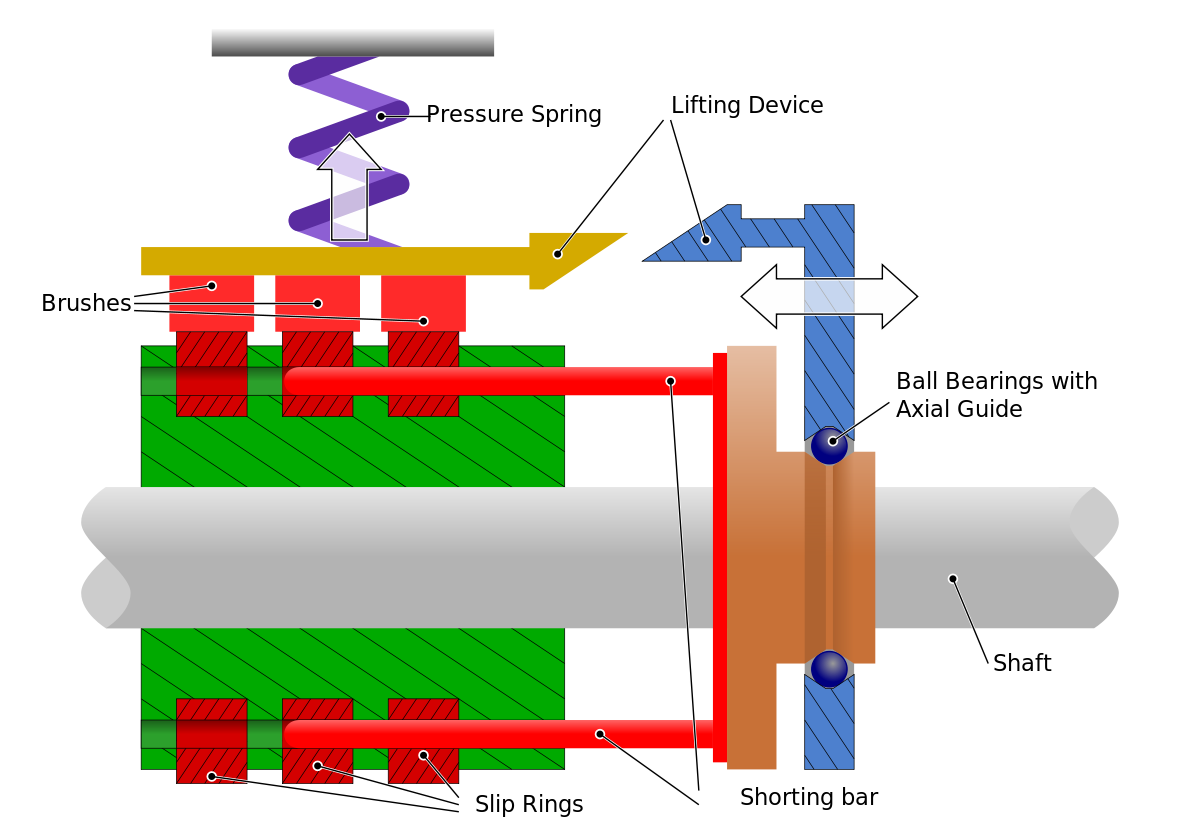

Figure 2: Main Slip Ring Components

Image Source: Moflon

Slip ring consists of only a few components, but it’s important to know their purpose. A slip ring is a basically stationary graphite or a metal contact (often a brush), which is made to rub the rotating part of a device (usually a metal ring).

As the metal ring turns, current or signal is conducted through the stationary brush to the metal ring, which makes a connection.

And even though slip ring is a very simple device, it has a very important role in many electrical devices which might not even be able to transmit signal and power without a slip ring.

How Does a Slip Ring Works?

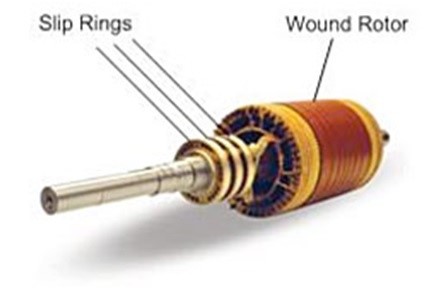

Figure 3: How Slip Ring Works

Image Source: Wikipedia.org

Since slip ring doesn’t consist of many components and it has only one purpose (and job to do), it’s really easy to understand how does a slip ring works.

By now, you understand that if you have an electrical device which features a stationary and rotational part – you’d have to transfer the power and signal from one to another.

This is where slip rings come in place.

Slip ring makes a contact through a stationary brush (metal contact) with the ring that turns. This allows the flow of signal and current from the brush to the metal ring – connecting the signal between the stationary and rotational part.

Even though this is a fairly simple design and it is an electromechanical device which provides a very basic action and purpose – thanks to its simplicity yet efficiency, slip rings have been used for decades now.

Of course, as we’ve mentioned earlier, there are a couple of different slip ring types which are just variations that come with a couple of more brushes or rings stacked along the rotating axis to match different machinery.

However, the principle stays the same and it will most likely always remain the same.

Why do we Use Slip Rings in Motors?

Figure 4: Slip Rings in an AC Motor

Image Source: Quora.com

Slip rings are very common to see in AC motors, but even though slip rings are a part of the AC motor, they have a different role, for this case.

In this case, slip rings are being used to insert resistance in the rotor windings. But why would a motor require resistance, especially in the rotor windings?

One reason only. To bring the rotor current more in-phase with a current of a stator.

Since AC motors don’t require signal or power transfer from a stationary to a rotary part – slip rings still create a lot of value by kind-of reversing its role and making a great fit into the AC motor.

However, even though you can find a slip ring in the AC motor, you won’t be able to find one in the DC motor. Instead of slip rings, DC motors rely on the commutators that reverse the current polarity in the windings. Such commutator is also known as a split ring.

Many people think of split rings as slip rings – so let’s clear out the confusion now.

What is the Difference Between Slip Ring and Split Ring?

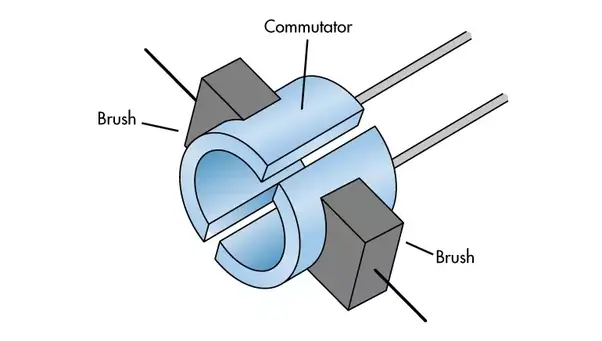

Figure 5: Split Ring Explained

Image Source: Quora

Someone without a lot of experience or knowledge on the topic would definitely mix these two terms up – however, they’re not the same thing and should never be misunderstood.

As we’ve previously mentioned, DC motors benefit from commutators such as split rings which change the current direction every half-rotation.

On the other hand, slip rings are invented to transfer signal and power from a stationary to rotary part of the device.

Not only these two have a totally different purpose and role, but they also work based on a different principle.

Conclusion

Slip rings are a very efficient electromechanical device, and even though they’re fairly simple when it comes down to the components or its working principle – they are still very effective.

They might have had some improvements over the last couple of years, but they’ve been almost identical for the past decade.

Of course, we can expect some smart and innovative versions of slip rings, but we don’t seem them being replaced anytime soon.

Hopefully, this article answered all your questions and if we made you feel like an expert on the topic – feel free to leave a comment below.

What did you like the most about slip rings? Its simplicity or working principle?