|

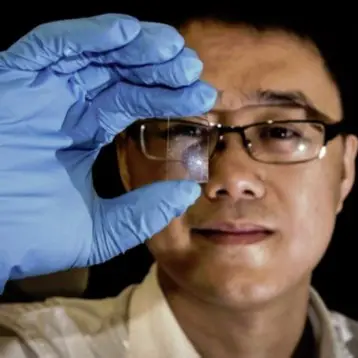

In trying to create the nanocomposite, the team tried to mimic nanostructures found in nature, such as those found in shells, bones, and tooth enamel. All consist of stiff ceramic platelets arranged in a polymer matrix, like bricks in mortar. The hybrid materials combine the strength of ceramics and the stretchiness of polymers.

Gauckler’s material, which is five times as strong as a material previously created at MIT, but is also stretchy. Film composite is as strong as aluminum foil and can be stretched to expand by up to 25 percent of its size, while regular aluminum foil would break at 2 percent.

|

The scientists created the material by dispersing aluminum oxide platelets in ethanol and spreading the mixture over water. The platelets arranged themselves into a single layer on the water’s surface. A glass plate was dipped into the solution, transferring the platelets onto the glass. A layer of biocompatible polymer chitosan was then deposited on top and the process was repeated until the final composite was a few tens of micrometers thick. The material was then peeled off the glass plate with a razor blade. The ratio between the length and thickness of the platelets has to be just right, said the researchers. If it is too high, the platelets break when the material is stretched. If it is too low, the material is not very stiff.

“This is the closest anyone has come to duplicating the mechanical structure and behavior of a natural material,” says Francois Barthelat, a mechanical-engineering Professor and biomimetic-materials researcher at McGill University, in Montreal, Quebec. But before the material can be used, he says, the researchers will have to develop a faster way to produce it in larger quantities. The technique should be easy to modify to suit bulk manufacturing, although Gauckler says that the material still needs to undergo many improvements before it can be practically used. For now, Gauckler says, “we have shown that we can (come close to) doing as good a job as nature.”

In 2006, TFOT covered buckypaper – “nanotubes on steroids”, as well as stretchy silicon chips, and stretchy silicon.

More about Ludwig Gauckler and his strong, stretchy materials can be found on the Swiss Federal Institute of Technology Zurich website.