|

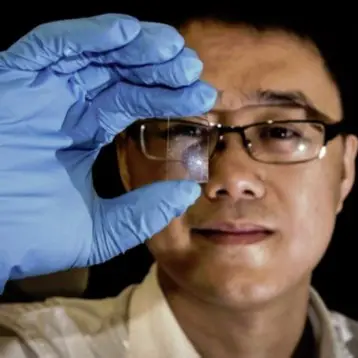

The scientists’ achievement is not only in creating a stronger kind of plastic. Working at the nanoscale, the UM scientists solved a problem that has perplexed engineers for decades; while individual nano-sized blocks, such as nanotubes, nanosheets and nanorods are extremely strong, larger materials composed of many of these strong individual blocks turn out to be significantly weaker. “When you tried to build something you can hold in your arms, scientists had difficulties transferring the strength of individual nanosheets or nanotubes to the entire material,” Kotov said. “We’ve demonstrated that one can achieve almost ideal transfer of stress between nanosheets and a polymer matrix.”

According to Kotov, one of the main reasons the material is so strong has to do with what he calls the “Velcro Effect”. The glue-like polymer (polyvinyl alcohol) and the clay nanosheets form hydrogen bonds within the layers of the material. If broken, these bonds can easily reform in a new place. Another factor contributing to the material’s strength is that the nanosheets are stacked like bricks – in an alternating pattern. “When you have a brick-and-mortar structure, any cracks are blunted by each interface,” Kotov explained. “It’s hard to replicate with nanoscale building blocks on a large scale, but that’s what we’ve achieved.”

The scientists name several possible applications for their invention. The composite plastic could be used in the making of stronger and lighter armor for soldiers and police forces and for protecting their vehicles. The material could also be used in micro-electromechanical devices, in micro-fluidics and biomedical sensors, in valves, and in unmanned aircrafts.

In 2006, TFOT reported on the development of Buckypaper, another material made from nanotubes, which was developed at the Florida Advanced Center for Composite Technologies (FACCT). The FACCT researchers have been working on combining this super strong material with other materials to create materials with even more advanced properties. More recently, TFOT reported on the creation of the longest nanotube by researchers from the University of Cincinnati.

More information on Kotov’s research can be found on the official website of Kotov Laboratory, at the University of Michigan.