The new study shows that the new potential efficiency is 30%, a significant increase in comparison to contemporary cells that have only about 20% efficiency. Using computer simulations, the scientists investigated ways to improve the performance of CIGS thin-film solar cells; these are important since they are only a few micrometers thick, and offer savings on material and manufacturing costs. Currently, CIGS thin-film solar cells absorb the sunlight through a thin layer made of copper, indium, gallium, selenium, and sulfur. There has existed previously a barrier to efficiency that, until now, scientists could not advance past.

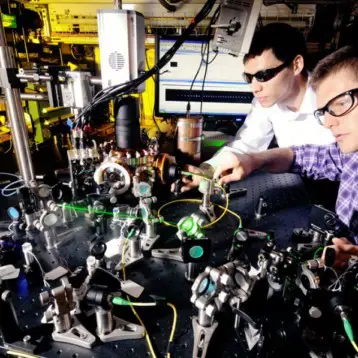

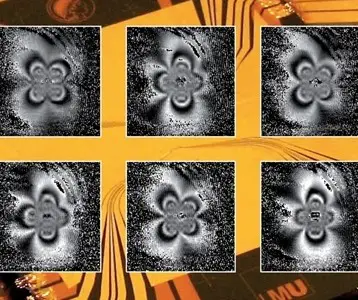

The research team at Mainz University, headed by Professor Dr Claudia Felser, has had its work published in the latest edition of the journal Physical Review Letters. According to their paper, they used computer simulations to investigate the characteristics of CIGS, derived from its chemical components. In this study, the team focused in on the indium/gallium puzzle that has been baffling scientists for years: What should be the optimized ratio between the two materials? Although it has been presumed that the optimal ratio should be 30:70, in practice, the maximum efficiency level has been achieved with the exactly inverse ratio of 70:30.

In order to solve this puzzle, the team received support from IBM Mainz. Using new calculations, specifically applying a hybrid method in which they used a combination of density functional calculations and Monte Carlo simulations, they found surprising results. "Density functional calculations make it possible to assess the energies of local structures from the quantum mechanical point of view," said Dr Thomas Gruhn, head of the theory group in Professor Felser’s team, whil explaining the methods used. "The results can be used to determine temperature effects over wide length scale ranges with the help of Monte-Carlo simulations."

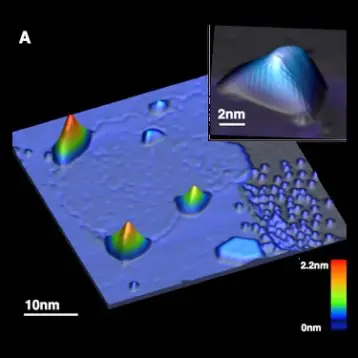

The simulations showed that the indium and gallium atoms are not distributed evenly in the CIGS material. There is a phase that occurs at just below normal room temperature in which the indium and gallium are completely separate. If the material is heated to above this demixing temperature, differently sized clusters of indium and gallium atoms do form. The higher the temperature, the more homogeneous the material becomes. It has now become apparent that gallium-rich CIGS is always less homogeneous than indium-rich CIGS.

This lack of homogeneity makes the optoelectronic properties of the gallium-rich material to be poorer, resulting in the low efficiency levels of gallium-rich CIGS cells. In fact, this is the first time this effect is being explained; the calculations also provide a concrete indication of the best way to manufacture CIGS solar cells. If it is produced at higher temperatures, the material is significantly more homogeneous. To retain the desired homogeneity, the material needs to be cooled down rapidly.

When trying to recognize prevalent difficulties, the team noticed that the limited heat resistance of the glass used as a substrate for solar cells is a major cause for the process’s imperfection. Fortunately, a breakthrough in this aspect was made as well. Schott AG has developed a special glass with which the process temperature can be increased to well above 600°C.

The resulting cells are considerably more homogeneous, meaning that the production of cells with a much greater efficiency level has become possible. But the researchers are already thinking ahead of this. "We are currently working on large-format solar cells which should outperform conventional cells in terms of efficiency," states Gruhn. "The prospects look promising."

TFOT has also covered bio-based solar cells, a new technology that produces bio-based materials from renewable plant sources, which could significantly reduce the cost of solar cells, and the Plastic Solar Cells created by Michael Gratzel, a Swiss chemistry professor.

For more information about the latest breakthrough in thin-film solar cells, see Mainz University’s press release.