|

Currently, industrial-scale printing processes can deposit electronics onto a variety of flexible substrates cheaply and speedily. The printed electronics require cheap printed power sources. For this reason, the new CNT batteries may potentially be an important advancement in battery technology.

The new batteries are deposited layer-by-layer in an all solution-phase approach amenable to large-scale production, similarly to roll-to-roll printing. The anode, which is the negative terminal where conventional current flows in, is made of Zinc foil, and also acts as a charge collector. It is followed by a separator soaked in a solution of ammonium chloride (NH4Cl) and zinc chloride (ZnCl2) electrolytes. The cathode, which is the positive terminal where current flows out, is then added on, made from a paste of manganese dioxide (MnO2), CNTs, and the same electrolyte mixture. A random CNT network on top serves as the charge collector, although any conducting nanowire could serve for the same purpose. The devices show an open-circuit voltage of approximately 1.45 V, with a total capacity of15-25 mAh. Although the batteries were only tested at low power, Prof. Gruner says his research team is working to increase the power output of the batteries and to demonstrate suitability of the designs for large scale industrial production.

Asides from the clear benefits of the solution-phase room-temperature process, there are even better news for future devices. The process lends itself to future one-layer-per-electrode designs; the anode and cathode could be just two nanowire-based mixtures as in the proof-of principal devices. This is a major advantage for simplicity in industrial scaling of the process, although the team is now focusing on optimizing their first devices before attempting to demonstrate an industrial-scale production.

Recently, TFOT covered the Hyperion Hydride Reactor, a sealed fission reactor that can supply power to a small community, as well as the Motion 2 Energy system, capable of channeling the energy created by movement into electric energy. Another related technology recently covered by TFOT is Enfucell’s “SoftBattery” – a 0.3-1.0 millimeter battery (1.5 or 3.0 V).

More on the University of California’s CNT printable batteries can be found here.

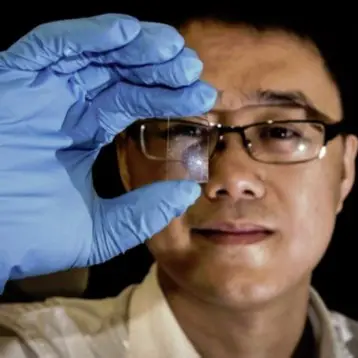

Top image: flexible Carbon Nanotube (Credit: California NanoSystems Institute).