|

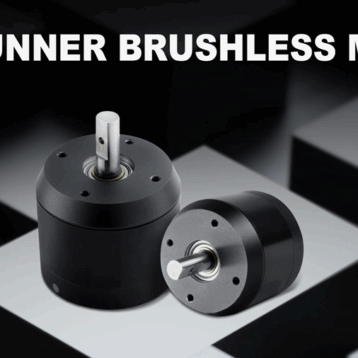

The researchers strapped a 200-micrometer tall metallic structure, dubbed a plasmonic collimator to the front of the laser source. At the top of the device is a horizontal slit just 2 micrometers high which is placed directly over the laser source. It is so narrow that around half the beam passing through is sharply diffracted towards the surface of the metal.The remaining light travels through the slit unimpeded.

As the rest of the beam hits the metal, the high-energy laser light turns into waves of energy rippling through the electrons of the collimator’s surface until they encounter a series of small horizontal grooves that jolt them back into light again. Redirecting the surface plasmons results in very little energy loss and as the distances between the original slit and each groove are chosen to ensure that all the beams emerging from the collimator are synchronized, they come together to form one tightly focused vertical beam.

The result is like a knife blade, sharpened in one direction but extending out in another. The researchers are now working on a version that can sharpen a laser in two dimensions, bringing it to a sharp point like a pencil.

TFOT recently covered such similar topics such as laser surgery that probes target cancer cells and micro-bonding laser chips using array beams.

More information on the plasmonic collimator can be found on the Harvard University website.