|

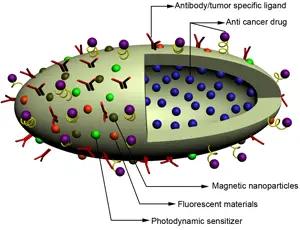

The electrical storage capacity of a Li-ion battery is limited by how much lithium can be held in the battery’s anode. Typically, the anode is made of carbon, due to the drawbacks of using silicon for this purpose. When silicon is placed in a battery, it absorbs positively charged lithium atoms as it charges, and then shrinks during use as the lithium is drawn out of the silicon. This repeated cycle of expanding and shrinking pulverizes the silicon, which causes the general degradation of the battery.

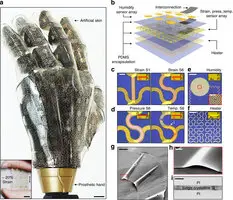

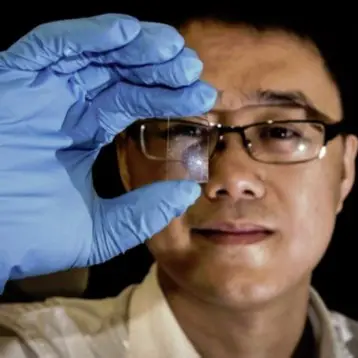

Professor Cui and his team solved this problem by using silicon nanowires grown on a stainless steel substrate. Once stored in the battery, the wires can inflate up to four times their original size when being charged, and do not fracture when the lithium is drained out of them.

|

Cui is considering establishing a company or reaching an agreement with a battery manufacturer for distributing the technology. Manufacturing the nanowire batteries would require “one or two different steps, but the process can certainly be scaled up,” he added. “It’s a well understood process.”

TFOT has covered several new advanced battery technologies, including Li-ion nano batteries that are considered to be much safer than existing batteries developed by researchers at the Tel Aviv University. A different technology developed by researchers at the University of California allows printing flexible Carbon Nanotube (CNT) based batteries.

More on the super Li-ion batteries can be found on Stanford’s website.