A Pressing Problem – An Innovative Solution

|

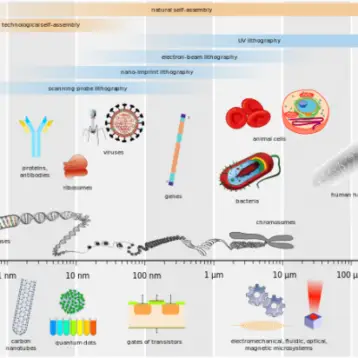

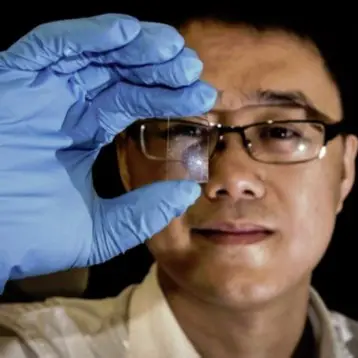

Moore’s Law, which governed the development of microprocessors since the 1960’s, dictates the doubling of the number of transistors on a processor every 24 months, resulting in ever-shrinking processors. The question arises, how do you wire these things in?” says Dr Jillian Buriak, University of Alberta Professor and Senior Research Officer at the National Institute for Nanotechnology (NINT). “If you’re going to make something on the order of 22 or even 18 nanometers (nm), then you’d better have a plug that’s about that size, too.”

Indeed, that’s just what the NINT team achieved. The scale of the wires is mind-boggling, one batch, for example, consisted of 25 parallel platinum nanowires, each less than 10nm wide. Compared with the average of 65nm nanowires currently used in the industry, the results represent a real breakthrough in micro-processing technology. The ratio aspect of the nanowires is equally impressive, with each of the wires extending 50 thousand times it’s width to a length of 50 microns.

Copying nature

Buriak sums it up:” We’ve figured out a way to use molecules that will self-assemble to form the lines that can be used as wires. Then we use those molecules as templates and fill them up with metal, and then we have the wires that we want. You use the molecules to do the hard work for you”.

Don’t be surprised if this concept reminds you of your high-school biology class. As is true for the basic concepts of many man-made inventions, the concept of self-assembly occurs in nature and in fact, serves as the basis for all living things. Buriak explains: “You are the product of self-assembly. The way DNA forms a double helix is self-assembly. It’s just that molecules will recognize each other, bind to each other, and then they’ll form structures…and the molecules we’re using are actually very simple. They’re just polymers, just plastics that do that naturally.”

While this concept is not entirely new in the nanotechnology industry, the NINT team’s “wet” demonstration of the technique and it’s successful results are groundbreaking. Their acheivement paves the way not only for mass production of smaller microprocessors, but also to new advancements in their design.

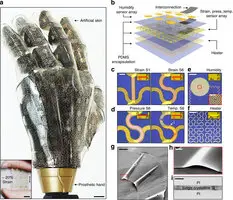

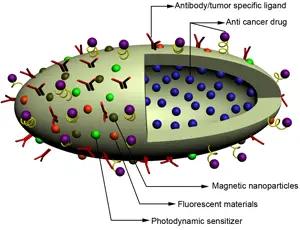

As mentioned before, the possible applications of the new method are numerous, from the field of computer industry to the medical world the hunger for smaller semiconductors is ever growing. With breakthroughs such as this one, a future where tiny microchips flow in our bloodstream, swim in our water, and float in our air – all for the benefit of mankind – is becoming more realistic.