In 1985, the fourth form of pure carbon (after graphite, diamond, and amorphous carbon) was discovered. Commonly known as a buckyball, or more formally, Buckministerfullerine, the molecule was named after Richard Buckminster (“Bucky”) Fuller, who, among a myriad of inventions, designed the geodesic dome with nearly the same symmetry. The buckyball is a large hollow, cage-like molecule with a distinct arrangement of 60 carbon atoms (C60) that form a spherical shape – a truncated icosahedron, similar to the hexagonal and pentagonal quilt patchwork pattern of the Telstar soccer ball, only with carbon atoms at its vertices and bonds along the seams. For their groundbreaking discovery of fullerenes, the family of symmetrical carbon-cage molecules of which the buckyball is the prototype, scientists Harold Kroto from the University of Sussex, and Robert Curl Jr. and Richard Smalley from Rice University shared the 1996 Noble Prize in Chemistry.

|

Six years later, in 1991, Sumio Iijima – a Japanese physicist at the NEC Corporation – who, while at Arizona State University, prior to the buckyball discovery had reported the same structure that had gone unnoticed at the time, was originally credited with the discovery of the carbon nanotube, a hollow, cylindrical fullerene that resembled needles of carbon under the high resolution electron microscope. However, preceding discoveries of nanotubes, notably in 1952 by Russian scientists L.V. Radushkevich and V.M. Lukyanovich, were known to the West only much later. In the late 1950s, Roger Bacon of Union Carbide observed hollow tubes of carbon, as did Morinobu Endo in the 1970s.

|

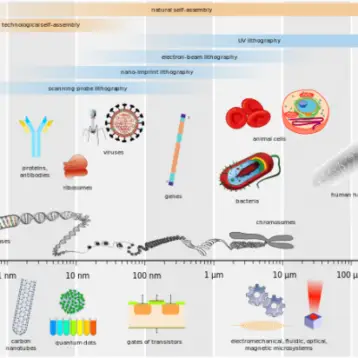

About 1/50,000th the diameter of strand of human hair, nanotubes – sometimes dubbed buckytubes – are lattices of carbon hexagons rolled into long strands. Various conformations of nanotubes exist – single-walled (SWNTs), multi-walled (MWNTs; which have concentric shells), doughnut-shaped torus (or nanotorus), and fullerite. Nanotubes exhibit unrivaled strength, flexibility, unique electrical properties, making the most conductive fiber known, can function as semiconductors, and are the most efficient thermal conductors. Each nanotube conformation displays unique strengths, hardness, kinetic, thermal, and electrical properties, with individual variants within a class differing as well. Thus, individual nanotube conformations could be targeted appropriately to the particular application.

|

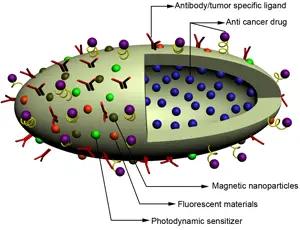

Despite extensive research throughout the world since the early 1990s into the unusual properties of fullerenes, their manufacturing and purification are still too complex and expensive for mass production. By combining carbon nanotubes with other materials, creation of nano-based composite materials, which are stronger, lighter, and capable of better thermal management than any known material, could have a myriad of applications. Attempts to integrate carbon nanotubes into composite materials proved disappointing, however, since nanotubes tend to stick together and are not easily dispersed, causing a dramatic increase in system viscosity.

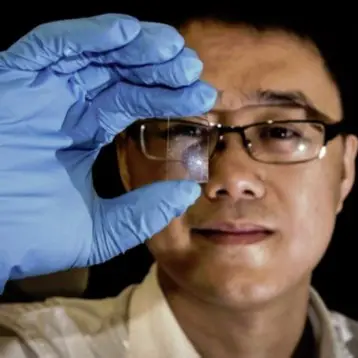

An inadvertent discovery in the 1990’s resolved many of these problems. When researchers from Richard Smalley’s laboratory managed to disperse nanotubes into a liquid suspension and then filtered it through a fine mesh, the nanotubes would stick to one another and collect on the filter, forming a thin film disk of pure nanotubes, later dubbed buckypaper. Research engineers, chemists, and physicists at the Florida Advanced Center for Composite Technologies (FACCT or FAC2T) directed by Ben Wang, Professor of Industrial Engineering at the Florida A&M University-FSU College of Engineering, have carried out pioneering research on the properties, bulk manufacture, integration into nanocomposites, and applications of ‘buckypaper’ since the year 2000, when Dr. Wang was first introduced to it. Touted as “harder than diamonds” and “stronger than steel at a fraction of the weight”, buckypaper, which has the potential for use in illuminating devices, heat sinks, armor, and electromagnetic protective skins, might help usher in a new age in material technology.

Q: What is buckypaper and what distinguishes it from existing carbon-nanotubes?

A: Buckypaper films are made up of nanotubes. They are thin flexible films (10-30 micrometers) with nanoscale porous structures and exceptionally lightweight (21.5g/m2 or 0.0705 oz./ft2). They have very unique properties. For instance, thermal management typically involves either brass or steel. Our aligned buckypaper films have been tested to indicate they are far better than steel and almost as good as brass, yet far lighter.

|

According to Dr. Richard Smalley, single-walled nanotubes are the strongest material known, have an electrical conductivity similar to copper or silicon, and a thermal conductivity greater than diamond. The key question is how to effectively get these properties into composites. Most past research on nanocomposites involved mixing nanotubes directly with polymer matrices to make nanocomposites. However, Van der Waals forces caused nanotubes in this case to group together and form ropes that could not easily be dispersed; it also resulted in a dramatic increase in system viscosity. Furthermore, lack of alignment of nanotubes in these nanocomposites is another major drawback, since nanotubes are highly anisotropic material and the most important properties are along the tube axial direction. Composite processing typically uses fiber matting or fabrics which are easily handled. Researchers at FACCT have developed buckypaper film which serves as the fiber matting that can easily be handled in composite fabrication. In summary, using buckypapers, we can achieve good dispersion and alignment of the nanotubes, avoid viscosity issues, obtain high nanotube loading, and provide a relatively easy scale-up ability for sizable nanocomposite part and device production.

Q: Does buckypaper have any properties that carbon nanotubes lack?

|

A: Although the buckypaper films do not have any properties that carbon nanotubes do not have, buckypapers provide the ability to effectively transfer the properties of nanotubes into composites. When direct mixing the nanotubes into polymer matrices, the nanotubes will group together and not disperse in the composite. Using our special filtration method, we can effectively disperse the nanotubes to make the buckypapers. The buckypapers can then be used as matting in composites to form nanocomposites that transfer the properties of the nanotubes into the composites. We have successfully transferred good dispersion, alignment, and high nanotube loading of buckypapers into bulk nanocomposites, which is a precondition for producing high-performance composite devices and structures. We have produced the world’s largest magnetically aligned buckypapers (60 in2). Our research demonstrates the processibility of using buckypaper for composites by developing a number of sizable prototypes of buckypaper composites for various custom uses.

Q: When was the first buckypaper produced?

A: Nobel laureate Dr. Richard Smalley’s group first produced nanotube film or buckypaper by filtering a nanotube suspension in order to prepare samples for various tests. During the past five years, we have built upon his work making the buckypapers larger and more multifunctional for composite fabrication.

Q: What are the main obstacles facing the commercial manufacturing of buckypaper and how do you think they will be solved?

A: Currently, we are producing buckypapers one sheet at a time, using basically an assembly line process. To make this commercially feasible, we must be able to scale up production. We have a developed a prototype for continuous production and we are planning to build a larger prototype in the near future. Also we have a concept plan for a process of continuous production of magnetically aligned buckypapers.

Q: What do you predict will be the main applications of buckypaper?

A: Based upon our ability to scale up production and the cost of quality single-walled nanotubes, we would expect the military to first take advantage of the technology, since they currently sponsor our nanotube projects. Buckypaper films can be added to aircraft to offer EMI (Electromagnetic Interference) shielding and lightning strike protection. They will also make the aircraft stronger and lighter, allowing for larger payloads and greater fuel efficiency.

In time, as production increases and nanotube costs go down, buckypaper film may be used in commercial aircraft and in notebook computers to draw away more generated heat without adding additional weight. Eventually, buckypaper nanotube films may be used by the automobile industry to make cars and trucks stronger yet lighter, and therefore, more fuel efficient.

Q: When do you expect to see the first applications of buckypaper?

A: We expect to see commercial or military use of the buckypapers in composites in about two to three years.