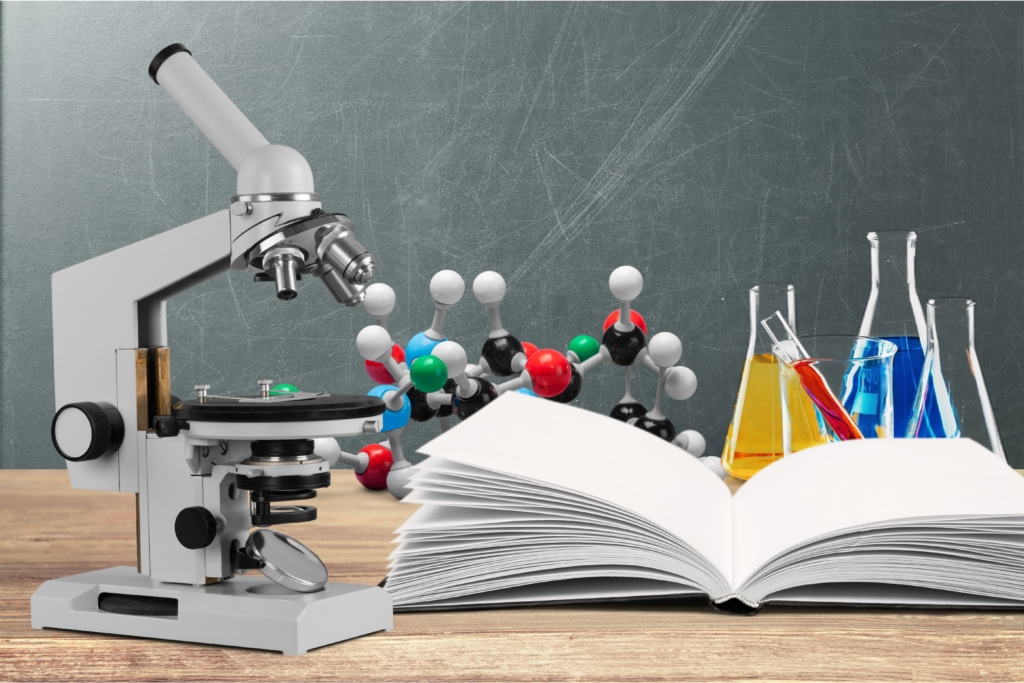

The metallurgical microscope was invented in 1863 by a geologist named Henty Clifton Sorby, who, among other things, also founded metallography, which is the study of metal’s physical components and physical structure through microscopy. Sorby made several important discoveries in different sciences; however, his most significant was the discovery of methods to analyze metals and minerals using a microscope.

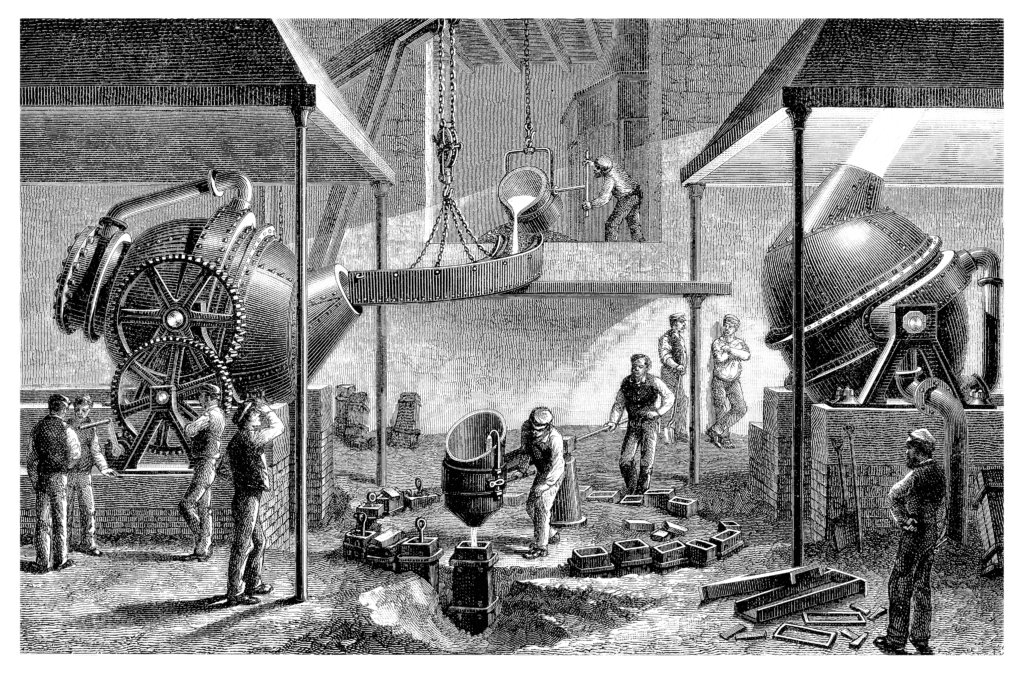

His discoveries in metal structure led him to understand that a specific quantity of carbon can make steel strong. This discovery led other scientists to develop methods of mass-producing steel, which enabled Britain to spark the Industrial Revolution.

So what does this microscope do, and how does it differ from other microscopes?

The Metallurgical Microscope

A metallurgical microscope is a type of high-power microscope used to view opaque objects. This type of microscope is different from the regular biological microscope because of the method of illumination used for the specimen; since opaque objects like metals are solid, they must be illuminated from the front, and not from under like the other optical microscopes.

This microscope’s light source is inside the microscope tube itself, which has a glass reflector installed. This makes the microscope ideal for examining metallurgical and other opaque samples like rocks, plastics, ceramics, and others.

Mr. Sorby’s invention is capable of high-magnification with different transmitted and reflected light options. This characteristic allows researchers and students to examine opaque specimens at extremely high magnifications.

Uses of Metallurgical Microscopes

This type of microscope is used in identifying flaws in metal surfaces, ascertaining the metal alloys’ crystal grain boundaries, and examining rocks and minerals. Due to its usefulness, the microscope is indispensable for any research laboratory, especially if the specimens examined are usually flat or shiny metals next to other surfaces.

Regular microscopes aren’t as effective with specimens like these. Metallurgical microscopes from microscopeinternational.com enable researchers to look closer because of the way the microscope uses light to reflect off the specimens. And since there are many areas where this microscope can be used, students and researchers find these microscopes indispensable.

Below are a few fields of studies where this microscope can be an invaluable tool:

1. Metallurgy

This microscope was specifically invented for use in this field, which refers to the process of extracting metals from ores. Using this tool will help you identify, examine, and observe metals and other opaque objects.

2. Archaeometallurgy

A subdiscipline of archaeology, archaeometallurgy is about metal artifacts and the methods of how ancient people acquired ores, as well as the types of technologies that were employed for smelting them.

3. Gemology

Deals with the study of natural and artificial gemstones. When valuation for commercial purposes is needed, a scientific approach is required to differentiate one gemstone from another. Metallurgical microscopes can be used for grading and valuing the stones.

4. Mineralogy

Refers to the study of minerals and their various chemical and physical properties, including their crystal structure. Mineralogists, using this microscope, will be able to know the variety, origin, age, and other traits of a mineral, which wouldn’t be possible with a standard optical microscope.

Types of Metallurgical Microscopes

The metallurgical microscope is basically made up of an illumination and optical system. This microscope has three types:

- Upright Microscopes – Most frequently used type, where the objective lens is above the specimen.

- Inverted Microscopes – Used for larger specimens, where the objectives are located under the specimen.

- Semiconductor Upright Microscopes – Has especially large stages and has the ‘throat’ depth to accommodate whole semiconductor wafers.

Components of Metallurgical Microscopes

A metallurgical microscope is optical, which makes it different from other microscopes in its system of specimen illumination. To examine metal or any other opaque material at a microscopic level, the illumination should come from lighting at the front, which is then mirrored back onto the specimen. The quality of the image that results for the user would depend greatly on the objective lens’ quality.

And because it is available in trinocular, binocular, and dual head, the user can take advantage of its expandability and flexibility. Moreover, you can choose any of the different types of metallurgical microscopes that would best suit your laboratory and your requirements; and as they are highly customizable, you can add special software for different applications, add microscopy cameras, or digital screens.

Various Magnification Tools

There are several types of magnification used in metallurgical microscopes. These are:

- Darkfield Illumination: This illumination is employed to create images with bright uneven structure characteristics, like etched grain boundaries, edges, and pores, on a dark background.

- Bright Field illumination: This type of illumination is best for creating images with a well-lit background and dark, uneven structure features.

- Nomarsky Prism: Commonly used in various interference contrast methods. This also lets the user study features not seen otherwise in brightfield magnification.

- Polarized Light: This is regularly employed by users to examine metals with non-cubic crystalline structures (like magnesium and alpha-titanium). The polarized light is made by a polarizer, which is found near the illuminator and analyzer.

Features of a Metallurgical Microscope

When it comes to eyepiece styles, this microscope has several. As mentioned earlier, these eyepieces include dual head, trinocular, binocular, and monocular. The eyepiece that has only one body tube and one objective lens is called the monocular eyepiece, while a binocular microscope has double eyepieces. The main reason for the double eyepieces is to reduce eye strain as well as muscle fatigue for the user.

Binocular microscopes are also utilized for their stereoscopic vision capabilities. This lets the user view the specimen with greater depth perception. Trinocular microscopes have a vertical tube on top, as well as regular binocular eyepieces, angled at 30°. The vertical tube is for a second user, or for a digital camera.

A dual head, besides having only one vertical eyepiece lens, also has a second eyepiece, located just at the side, angled at 45°. This enables two users to observe a specimen at the same time, or one user plus a camera. Other essential features in a metallurgical microscope are mechanical stages, digital display, fine focus, image analysis processing software, and computer interfaces.

Conclusion

The inventor of the metallurgical microscope is a British scientist named Henry Clifton Sorby. His instrument led him to discover steel’s composition and what gave the metal its strength. His discovery helped other scientists to invent processes of mass-producing steel, which made the Industrial Revolution possible.

Today, his discovery, the metallurgical microscope, has evolved to be even more useful, and is used in different fields of study. Over the years, features were added, lenses were improved, and different modern technologies are now integrated into the microscope. This microscope has greatly helped advance knowledge in many different fields of study and has become an indispensable tool among researchers and students.