Professor Linda Nazar, lead researcher on the project, explains that lithium-sulphur batteries have long been attractive to scientists due to the higher energy densities that sulphur provides when paired with lithium. Additionally, sulphur is relatively inexpensive in comparison with other materials used in lithium batteries and allows for a safe, low cost, long lasting rechargeable battery with low carbon emission energy.

“The difficult challenge was always the cathode, the part of the battery that stores and releases electrons in the charge and recharge cycles,” said Dr. Nazar. “To enable a reversible electrochemical reaction at high current rates, the electrically-active sulphur needs to remain in the most intimate contact with a conductor, such as carbon.”

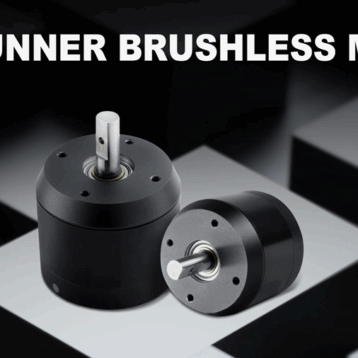

The team developed solutions to increase performance at a nanoscale level. A mesoporous carbon was used to start off the process. This carbon is highly structured, porous and at a nanoscale has a much uniformed pore diameter and volume.

A nano-casting technique was employed to assemble carbon rods that have a diameter of 6.5 nanometers into channels three nanometers wide. To keep the empty channels and carbon rods in position and contain the structure, carbon microfibres were inserted. To fill the nanoscale voids, the team bonded heated and melted sulphur on top of the carbon nanorods. The sulphur flows and is imbibed into the channels by capillary forces as it shrinks to form sulphur nanofibres.

The research team continues to study the material to work out remaining challenges and refine the cathode’s architecture and performance. “This composite material can supply up to nearly 80 percent of the theoretical capacity of sulphur, which is three times the energy density of lithium transition metal oxide cathodes, at reasonable rates with good cycling stability,” said Dr. Nazar. A patent has been filed for the process and commercialization is already being planned.

TFOT has previously written about Toshiba’s speedy recharge battery that can be recharged to 90 percent of its capacity with a current of 50 amperes (A) in less than five minutes. We have also written about nanowire batteries, able to produce ten times the amount of electricity of a comparable Li-ion battery.

Additional information on the Sulphur-Lithium batteries can be obtained here and more can be found at Dr. Nazar’s project website.

Icon image: A schematic diagram of the sulfur (yellow) confined in the interconnected pore structure of mesoporous carbon, formed from carbon tubes propped apart by carbon nanofibres. (Credit: Nature Materials)