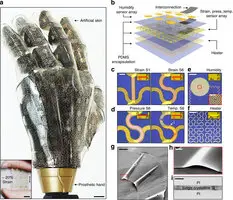

Researchers at the University of Illinois have developed a new ink that can be used in electronic and optoelectronic applications to produce flexible, stretchable, and spanning microelectrodes that transmit signals from one circuit element to another. The ink, which is made from silver nanoparticles, can last through constant bending and stretching with negligible change to their electrical properties. The new ink could be used in the future to improve LED arrays and advanced solar mico-cells.

|

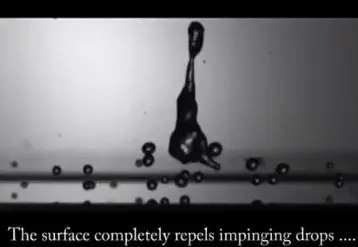

4×4 GaAs LED array interconnected with

spanning silver microelectrodes.

(Credit: Jennifer Lewis) |

|

The team at the university exhibited patterned silver microelectrodes by omnidirectional printing of concentrated nanoparticle inks with a miniscule width of 2 microns on semiconductor, plastic, and glass substrates. “Unlike inkjet or screen printing, our approach enables the microelectrodes to be printed out-of-plane, allowing them to directly cross pre-existing patterned features through the formation of spanning arches,” said Jennifer Lewis, the Thurnauer professor of materials science and engineering.

The process of developing the printed features starts with the researchers preparing an extremely concentrated silver nanoparticle ink, which is then guided out through a narrowed cylindrical nozzle connected to a three-axis micropositioning stage. This would be all handled by computer-aided design software.

When the silver nanoparticles have been printed, they still have not bonded together yet. The printed structure is subsequently exposed to a high temperature of 150 degrees Celsius or higher. These nanoparticles then fuse in a process called

thermal annealing into an interconnected structure.

The printing process was put through its paces by creating printed patterns with both planar and out-of-plane silver microelectrodes that could be used in a number of applications, such as in spanning interconnects for solar microcell and

light-emitting-diode arrays. A planar silver microelectrodes are interconnects that have been designed in two dimensional form, whereas an out-of-plane represents a three dimensional. For example, using bonded silver wires in three dimensional devices.

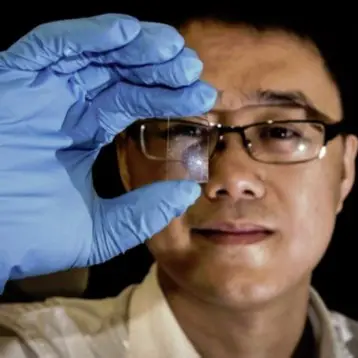

“Unlike conventional techniques, our approach allows fine silver wires to be bonded to delicate devices using minimal contact pressure,” said postdoctoral researcher Bok Yeop Ahn, the lead author of the paper. This approach can also create highly integrated systems from a range of electronic materials on a comprehensive array of substrates. This technique has the capability to overcome the drawbacks associated with omnidirectional printing.

Additional information on the new ink can be obtained at University of Illinois’s

website.