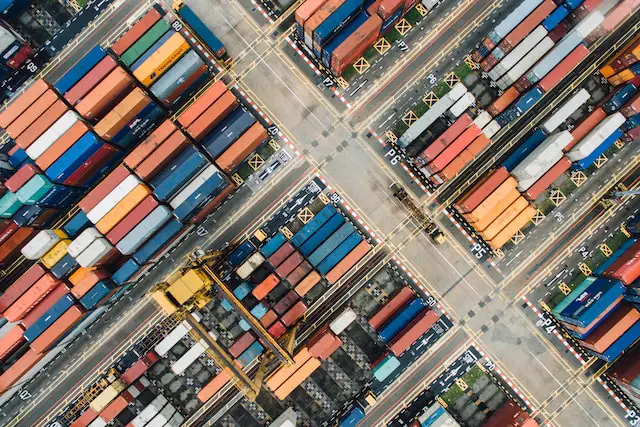

The supply chain industry is going through continuous challenges, especially after the COVID-19 pandemic that disrupted most of the companies’ regular processes. Hence, we can say that global illness triggered problems at the core of many sectors, especially healthcare, but also management, manufacturing and exporting of products and raw materials.

Navigating the pandemic and upcoming geopolitical conflicts and changes, we’ve come to notice how the supply chain is affected worldwide. First, freight prices increased due to a lack of proper shipping capacities and booming product demand. However, the limited supply of raw materials required to manufacture the end product is limiting companies that already have trouble forecasting demand. On top of that, the immediate situation of global warming must also be considered, but it would require a total shift in the supply chain to truly showcase results.

Besides retail, transportation and entertainment, one prominent sector was considerably affected by these disruptions ―the food industry. Considering its immense importance for the worldwide population, emerging technologies and approaches are tested to improve the sector definitively. Here’s how.

Shifted focus on high-protein foods

Sustainability, expanded possibilities, and in-depth research slowly led to a lifestyle based on plant-based meals as an alternative to meat and highly processed products. Since customer behavior regarding nutrition and its environmental impact has changed dramatically in the past years, companies are looking for ways to appeal to the demand.

But besides approaching to create and sell these products, the main problem of a food ingredient supplier is handling its greenhouse gas emissions, water and land usage, pollution and animal welfare, which wouldn’t all count as problems for alternative proteins. As we can see, maintaining a balanced and sustainable approach is quite challenging, so focusing on high-protein foods will probably bring better outcomes within the supply chain in the next few decades.

Automation through AI

The rise of AI in the past year provides a brand-new possibility for the supply chain to become more put together and mitigate cargo theft. Leveraging artificial intelligence could transform current processes into transparent, efficient and resilient steps of the supply chain. For example, generative artificial intelligence would be proper for forecasting demand considering the ever-changing customer trends.

However, discovering what automation could become through AI in this sector expands significantly when we see that many objectives could be realized with this approach. Customer service becomes more straightforward, procurement is more time-efficient and mitigating labor risk is possible with minimum effort. Even transparency is brought to the next level through genuine accountability and proper algorithms, but it’s one of the biggest issues in supply chains, especially in traditional ones. For instance, a nuts manufacturer or supplier might get their nuts from intermediaries who get them for small holders, which hinders local processing at the origin and, therefore, traceability.

Mitigating unpredictability within the geopolitical landscape

Similar to any other sector, unpredictability in the supply chain is one of the most damaging factors that leads to disruption. Let’s take the example of extreme weather implications, which can cut off exports of essential aliments, such as rice and grains, that completely destabilizes food chains and affects global food shortages. The complexity of preparing for such events is difficult to handle, but analyzing financial exposure to the weather system and its impact on the sector’s performance is vital for a constant flow of food supply movement.

More interest in building resiliency is required for B2B food partnerships. Still, these risk management projects should be based on transparency, automation and shared views on the demanded products from the end consumer. The “what-if” business model is a significant help for those involved directly in the supply chain because it helps measure the lengths to which various independent and dependent variables lead to a specific outcome.

Strict regulations and new guidelines

As the world changes, the legal framework in which businesses can delegate tasks is also shape-shifting pretty fast. Such movement will also include the supply chain industry, where countries will adapt to new guidelines from the government based on exacerbated environmental, social and digital challenges.

For example, the agricultural sector will transition considering the changing circumstances of climate change and geopolitical demands, meaning it might get more or less accessible for farmers to provide raw materials. Hence, disruption and lack of enough produce should be expected in the future, for which the legal framework will adapt. There’s also an ongoing issue with mitigating zero-emissions transportation, for which an upcoming regulation should be implemented right at the beginning of 2024.

Enforced worker safety and education

Although it’s an underrated factor in the supply chain industry, the company culture needs a reset. So, it should be expected that in the future, supply chain companies will prioritize diversity and inclusion as well as enhanced safety features in order to attract new employees and nurture loyalty. This aspect could be improved through supplier diversity, for instance, where minority-owned businesses help foster economic growth in their area and get to collaborate with prominent figures in the industry.

Another solution for improving worker safety includes ethical sourcing that should be based on fair labor prices and human rights. Enhancing awareness on this subject could ensure education and training towards suppliers and employees, impacting the entire supply chain industry in a matter of years. Finally, improved company culture leads to access to proper performance metrics and evaluation of workforce diversity and inclusion initiatives, which is a huge step ahead for the entire economy.

Final considerations

For 2024, we hope the supply chain industry will approach change with open arms, settling for solving some of the biggest problems in the sector. Transparency, traceability and new regulations are required to set a healthy and prosperous standard for companies because their impact affects the environment, the workforce and the inclusion of the circular economy. Of course, adopting technology is a main quest for supply chain investment since the use of AI and automation can clear the path towards sustainable and fair practices. However, collaborating with other companies is crucial for exchanging information, offering support to small businesses and lowering their contribution to landfills.