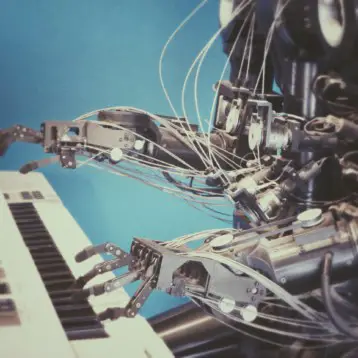

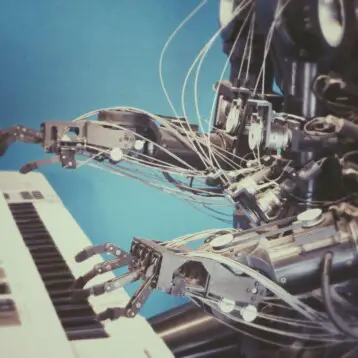

The human body is incredibly versatile, its structure is light and the human organism operates with an incredible efficiency. The human arm, including the hand and the shoulder joint, consists of 64 muscles and 28 bones, and numerous receptors for temperature, position, tactile sensation and pain. The special structure of its joints allows us to develop strong forces, move our arm and fingers easily in almost any direction, and perform delicate operations, such as grasping. These characteristics are the main targets for robotics specialists.

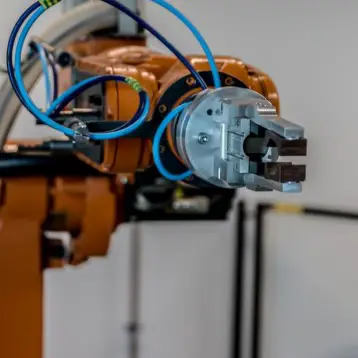

Airic’s Arm’s bone structure is operated by a total of 30 artificial muscles, which were also developed by Festo and are known as “Fluidic Muscles”, used in various industrial applications. These muscles are made of tubes of elastomer reinforced with aramide fibres. When a Fluidic Muscle is filled with compressed air, its diameter increases and it is simultaneously shortened. These artificial muscles have immense starting power, and their dynamic behavior is similar to that of human muscle tissue. Surprisingly, the robotic arm has one important advantage over its flesh and bone counterpart: when the arm is contracted, it requires no further supply of energy – for example, it can lift weight and hold it in the same position indefinitely. The bone structure itself consists of the ulna and radius, metacarpal and finger bones, a shoulder joint and shoulder bone-joints.

The computer-designed bones were grown in a three-dimensional polyamide structure using laser sintering process. 72 proportional valves, along with pressure sensors and power electronics in the form of 8 valve modules were applied to achieve reliable muscle control. The tensile forces and the contraction of individual muscles are measured by pressure and length sensors, and a special mechatronic unit regulates the pressure distribution within the system, allowing a close similarity to the kinematics, rapidity, force and refinement of a human arm.

Festo intends to further develop its mechatronic systems by integrating cameras and tactile perception elements into the devices, thus extending the sensory state of its products. The company plans to continue designing robotic human parts, such as a back, a hip and a neck, within its bionic projects.

TFOT has previously covered the “Shadow Hand” – a robotic arm developed by the English company “Shadow Robot”. Their development uses Air Muscles that provide a pulling force to the hand. These muscles contract to up to 40% of their original length when actuated with a supply of compressed air and can provide a powerful source of force.

More information on Festo’s robotic arm and other products can be found on the company’s official website.

Further discussion of Airic’s Arm can be found on the TFOT forums.