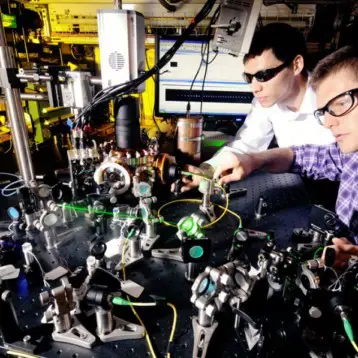

Understanding how and why coatings fail has broad applications in the physical and biological sciences, according to the lead author of the study, Eric Dufresne, associate professor of mechanical engineering at Yale University. He has led a team of scientists, who published their research in the Proceedings of the National Academy of Sciences. Team members are from Yale, Princeton University, and Unilever Global.

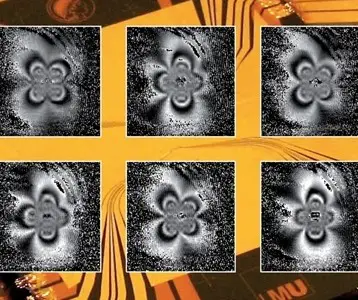

In their study, the team presented a new way to image and analyze the mechanical stress that causes colloidal coatings – those in which microscopic particles of one substance are dispersed throughout another – to peel off of surfaces. According to Dufresne, coatings protect almost every surface we encounter, “from paint on a wall to Teflon on a frying pan to the skin on our own bodies,” he says. “When coatings peel and crack they put the underlying material at risk. Our research is aimed at pinpointing the failure of coatings. We’ve developed this new technique to zoom in on coatings and watch them fail at the microscopic level.”

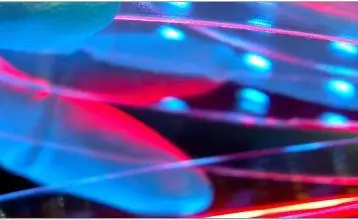

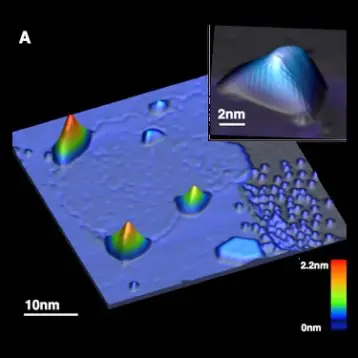

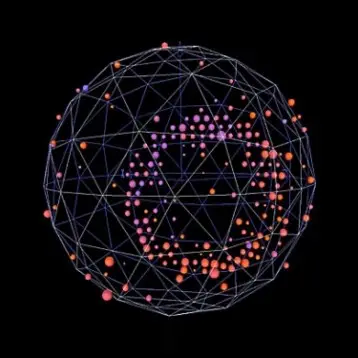

The research offers a method that creates three-dimensional visualization of the coatings. To do so in the microscopic level, the scientists mixed in tiny fluorescent particles that glow when illuminated by a laser. As the team traced the motion of these particles over time with a microscope, they captured the motion of the paint as it peeled and dried in detail.

Another benefit of this method is being able to track the 3D forces generated by the paint as it dried, resulting in a detailed “stress map” of the mechanical deformation of the coating. Hopefully, it will help understand the causes for its failure. “The trick was to apply the paint to a soft surface, made of silicone rubber, that is ever so slightly deformed by the gentle forces exerted by the drying paint,” Dufresne said.

Although the current study focuses on colloidal coatings, the technique could apply to all kinds of coatings. “This is a completely new way of looking at a very old problem,” said Dufresne. He adds that the team’s next step is to improve current methods for mitigating peeling in a wide range of coatings.

TFOT has also covered electrospun fibers, which could prove useful in a variety of applications such as protective clothing, drug delivery, and tissue engineering. Another related TFOT story is on the subject of ArmorLite, an innovative coating for compact fluorescent lights that prevents the release of toxic mercury when bulbs break

For more information about the mechanics of colloidal coatings, see Yale University’s press release.