|

Optical fiber technology is used in modern communication systems to allow high-speed transmission of data. Its infrastructure relies on multiple precise connections of laser-to-fiber and fiber-to-fiber across the transmission lines. “Passive” fiber connectors, which are typically used for low data transmission multimode fiber, are relatively inexpensive, but do not have the microscopic precision required to align high speed data on single mode fiber cores. This type of connectors use a guide to hold fibers in place. The expensive and bulky “active” connectors systems use lenses and cameras to align the fibers, which they later hold in place by applying an epoxy resin, by soldering or by laser welding. These systems can be severely damaged as a result of changing weather conditions, such as moisture or seasonal temperature changes, making them less reliable and increasingly costly.

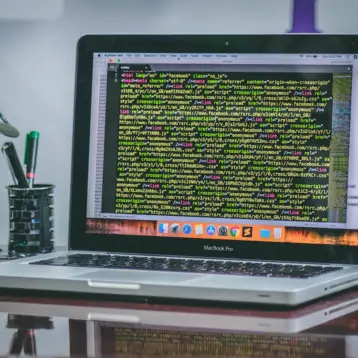

The Integrated Fiber Alignment Package (IFAP) is based on the low temperature co-fired ceramic (LTCC) technology, widely used in electronics packaging for its durability and design flexibility. An ultrasonic micromotor, integrated into a low temperature co-fired ceramics package, controls a slider, which in its turn holds and adjusts the position of the fiber with 2-degrees of movement and a 100-nanometer precision. The motor is controlled by an external drive circuitry with optical intensity feedback, which allows precise alignment, and, if necessary, realignment of the fibers in the field. The external drive circuitry can be connected to a laptop computer and adjustments can be made using the computer’s mouse or keyboard.

|

The scientists say that their invention and the unique fabrication process simplify the alignment of fibers and combine the precision of expensive active connector systems with the convenience of passive connectors that mechanically hold fibers in place. “Our new product can provide a cost-effective method for active alignment with high precision and in a compact size. In addition, the re-alignment function of the package would reduce the laborious fabrication process and elongate the life time of the optical module. In conclusion, fast and reliable optical data communication will be improved with this new packaged alignment system” – they said.

More information on the IFAP can be found here and here. TFOT already covered a number of advanced high speed data transfer technologies on “High-Speed Data Delivery – Fact or Fiction?“.

Further discussion of this technology and its applications can be found on the TFOT forums.