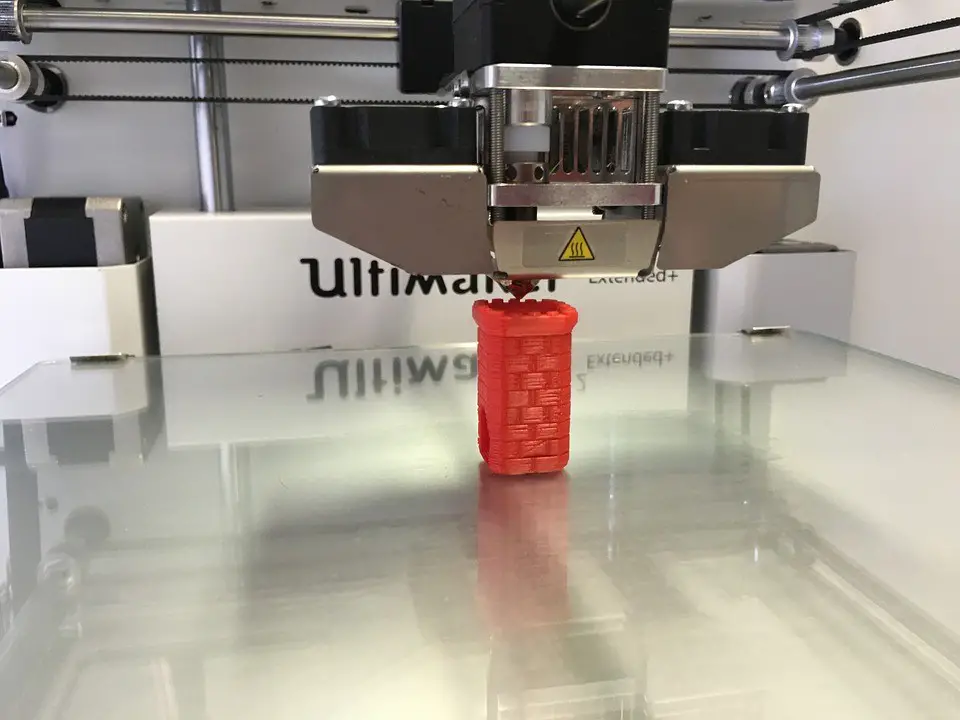

The experience of 3D printing has taken the entire world by storm and a number of people are approaching this idea as it is very reasonable as well as time-saving. However, there are a few lesser-known efficiencies about 3D printing that do not grasp a lot of headlines.

Following mentioned are the seven ways using which you can boost your 3D printing efficiency:

- Materials:

The material of your 3D printing is considered to be of high importance in order to experience the best 3D printing. In terms of the price, material pricing may vary considering their physical, chemical as well as mechanical compositions. Thus, you must always pay attention to what material are you taking into use in order to get the best 3D printing experience. At the same time, you must remember that all those projects that require strength demand a better material than the normal ones.

- Technologies:

Technology, while 3D printing, plays a pivotal role in figuring out the overall cost as well as build speed of the parts. While some of them give you the quickest of results, others are considered to be relatively slow. Thus, all these factors must be taken into consideration altogether while choosing the technology for your printing experience. Determination of technology could be done based on the parameters of the project that you are working on.

- Layer height:

The layer height of the part depends on the purpose for which it is to be used. If it is cosmetic in nature, then the thinner layers are the best pick. The catch here is that the thinner layers avoid all kinds of inherent ridges of the 3D printing and thus the results look more impressive and superlative.

- Part orientation and supports:

The level of support that a part wants is totally based on its orientation. In order to lower the costs, the parts should be oriented in such a way so as to reduce the number of necessary supports. Thus, this would require a lesser amount of material.

- Wall thickness:

Selecting a right wall thickness needs a balanced approach. All the parts having thinner walls need less build time, at the same time they come with a lot of risks. Walls which are thin could result in warping, flimsy features and even uncalled for fragility. Thus, you must review all the relevant technologies and materials after defining the intended function in order to select the best part’s best-desired wall thickness. For this purpose, each part must contain its own guidelines as to thickness which would further help the users to determine a path forward.

- Sparse-Fill:

The design freedom of 3D printing is considered to be one of the best benefits. It makes way for all the intricate parts in order to be built in such ways that the typical manufacturing experience cannot match it. In order to get the best outcome, you must choose the option of sparse-fill which could be offered to you by Stratasys Direct Manufacturing for Stereolithography (SL) as well as Fused Deposition Modeling (FDM). This option offers you a faster built with the involvement of fewer materials which eventually reduces your hefty budget. This option is considered to be a safe as well as wise choice.

- Additional labor:

Finishing and post-processing are nothing but the parts that demand a pristine cosmetic finish. Thus, it is very important for you to analyze the needs of your project beforehand so as to avoid unwanted printing hassle. You must consider that only a few sections of a part might demand some sort of extra polishing as well as be finishing in order to be able to perform all its intended functions. You can also look for different filament types and the use of all the other accessories that are involved in the context of giving some extra attention to your project.

Keep these seven considerations in mind and start building your 3D printing by putting your best foot forward.